Technical

The case for steel – Steel meets stringent NHS vibration requirements

The new Birmingham Acute and Adult Psychiatric Hospitals, the largest NHS development outside of London, is using more than 12,000t of structural steel

The latest in our Case for Steel series highlights how steel frames meet vibration and acoustics requirements.

The need for varying room and ward sizes meant that steel was used for the extension to the main hospital in Guernsey

The need for a quick construction programme makes steel the preferred method for hospital construction

All structures are susceptible to vibration, whatever material they are built from. Floors of steel framed buildings have always performed in line with requirements of the varying and demanding uses to which they are put. Physical tests on finished steel framed buildings show that the measured vibration is generally less than predicted by current calculation methods, and no special measures need be adopted for vibration on any steel framed buildings.

The most exacting vibration standards for floors are demanded by the UK’s National Health Service for operating theatre areas. The same design of floor that commands over 70% of the multi storey buildings market delivers the health service what it wants.

Intensive studies have shown that steel framed buildings provide floors with vibration performance that surpasses those stringent specifications, while still delivering all the advantages of steel like cost effectiveness and flexibility to the UK’s vitally needed health investment programmes. Health service professionals value the ‘future proofing’ that the easy adaptability of a steel framed building provides.

Designers have on occasion opted for a ‘belt and braces’ approach and provided additional strengthening in sensitive areas of hospitals, but in these cases the steel framed structure still emerges as the more cost effective option. The long span solutions that only steel can provide can in fact be even more appropriate for vibration sensitive areas as the greater mass that participates in the vibration motion tends to reduce the dynamic response, so there is less vibration.

Designers and contractors providing healthcare facilities of all types, whether being procured through traditional contracting or Private Finance Initiative type routes, are specifying steel framed buildings so that the cost, programme and other advantages of steel can be captured.

Detailed guidance is available from Corus and the SCI on how steel structures can be checked to ensure compliance with vibration performance criteria.

Careful detailing solves acoustic issues

The acoustic performance requirements of Part E of the Building regulations are easily satisfied by steel framed buildings without any special measures. It is sometimes thought, naively, that heavy concrete construction is an easy way to ensure acoustic performance. Careful detailing is required with any framing material to ensure compliance with Part E, including floor finishes, service penetration and flanking details.

Compliance with Part E must be demonstrated by post-completion testing, or by the use of approved details known as Robust Details.

Robust details of proven reliability are available for floors, walls and flanking connections. Details are continuously being developed. Construction details are available for:

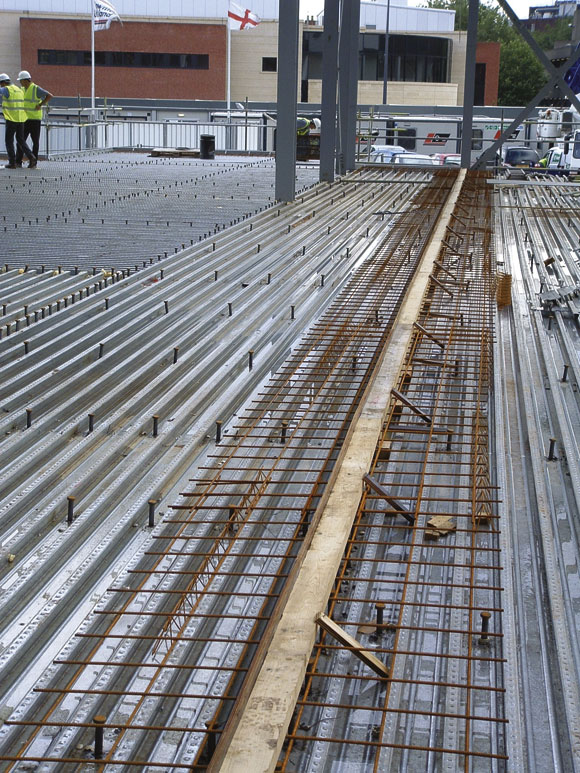

- Composite floors

- Slimdek

- Steel columns in blockwork walls

- Light steel framing systems, including infill walls

Infill steel construction easily meets the criteria for acoustic and thermal insulation. Infill steel solutions do not suffer, as does blockwork for example, from having to be carefully constructed on site without gaps, particularly where it meets the main structure.

Steel hospitals outperform

Tests on floors in steel framed hospitals show that they out-perform the National Health Service requirements on vibration response.

The research, carried out by the Steel Construction Institute in 2005, confirms that good vibration performance can be achieved from composite floors in steel framed hospital buildings without any additional measures being taken.

The tests followed release of new design guidance from the Steel Construction Institute (SCI) in 2004 that laid to rest out-dated notions that uneconomically heavy steel sections would be needed to provide the vibration performance demanded by health professionals in sensitive areas like operating theatres.

SCI carried out tests on five composite floors in four hospitals with overall slab depths of between 175mm-337m. The measurements surpassed the NHS requirements by a factor of between two and four. On a fifth floor tested it was found that an 80mm screed could have been omitted and the slab reduced theoretically from 325mm to 240mm, and an acceptable response factor would still have been achieved. The hospitals tested included the Slimdek floors at the Treatment Centre at St Richard’s Hospital, Chichester, and the Sunderland Royal Hospital extension, both built within the previous four years.

The test results conclusively rebut allegations made by the Concrete Centre suggesting that steel framed floors would need to be significantly deeper to achieve the NHS required response factor of 1.0 (equivalent to a slab depth of 420mm plus a 50mm screed). The new tests showed a response factor of only 0.29 being achieved on a floor that was in fact 14% thinner.

Measurements from five floors have showed that steel framed floors are capable of achieving the strict vibration requirements for operating theatres. The implications of these test results are that designers can be confident that Slimdek floors in the health sector do not have to be designed any differently from floors in commercial buildings. There is no need to do anything extra to achieve good vibration response factors.

Hospitals and other healthcare buildings now routinely benefit from the full range of benefits of using steel frames that have brought steel a dominant share of the commercial market, says Corus General Manager Alan Todd. ‘Hospitals have to be built quickly because there is such a pressing need for them, which brings steel’s fast construction time into its own. Health professionals also want flexibility built into hospital designs to accommodate changing needs, which steel with long, clear spans can easily offer. Steel is still also the most cost effective framing option, as recent Cost Comparison studies have showed.’