Projects and Features

Stronger steels in high demand

ArcelorMittal reports increasing use of high strength steels offering weight and cost savings across the worldwide markets that it operates in, as Neil Tilley tells Nick Barrett.

ArcelorMittal reports increasing use of high strength steels offering weight and cost savings across the worldwide markets that it operates in, as Neil Tilley tells Nick Barrett.

Steel manufacturer ArcelorMittal can lay claim to a near 100 year history of experience supplying the UK and Ireland markets. The company is now active in 60 countries worldwide and has an industrial footprint involving mining or manufacturing in 19 of those.

It is acknowledged as a world leading producer of structural steel shapes and is a leading supplier of quality steel products in major markets across the construction, automotive, household appliances and packaging sectors.

The company maintains a global research and development effort and a worldwide network of operations like dedicated sales and market support teams.

ArcelorMittal says it can provide whatever steel solution is needed, rolling all the standard sizes required in the UK and also some unique products of its own. Neil Tilley, Senior Technical Sales Engineer & Business Development at ArcelorMittal Europe – Long Products, says: “The company has been active in the UK for many years and is increasing its commitment to the market in several ways. For example, we are Headline sponsors of the Steel for Life marketing initiative and are offering support to designers.

“We offer a full range of sections and other steel products as well as having some innovative specialist products in the range, like our high strength and low alloy steels. We can offer the bigger sections that many projects now depend on.

“There is a very high commitment to sustainability at ArcelorMittal. We have recently adopted a Sustainable Development Framework that drives and shapes a consistent approach to sustainability in all the countries we operate in.”

High strength and low alloy steel grades

ArcelorMittal says it is seeing an increasing use of high strength steels around the world as engineering designers and steelwork contractors capitalise on their advantages. One of these is that weight and cost savings of as much as 20% can be achieved by using high strength steels.

Another type of steel seeing increasing interest is low alloy content steels such as those in ArcelorMittal’s HISTAR range. HISTAR steels are structural grades with a low alloy content, combining high strength, good toughness and superior weldability, available with minimum yield strengths of 355 or 460 N/mm².

They are said to feature improved guaranteed mechanical characteristics over the whole range of product thicknesses.

ArcelorMittal‘s Neil Tilley said: “We offer a wide range of high strength steel grades, which are finding an increasingly wide range of applications. As well as our conventional S355 steel and high strength S460M steel, we are seeing growing use of steel capable of exceeding the standard requirements, such as our HISTAR 355 and HISTAR 460 steels.

“An outstanding feature of these high strength steels is their low carbon equivalent values, which allows easier processing by steelwork contractors, which means preheating before welding can usually be avoided, allowing substantial time and cost savings.

“Engineers around the world are taking advantage of HISTAR steel in gravity columns of high-rise buildings, axially loaded members in long-span trusses and in seismic design.”

In order to best suit the different applications, HISTAR grades are available with guaranteed toughness to -20° C and -50° C. They are delivered in the thermomechanically rolled condition in accordance with the European Technical Approval ETA-10/0156.

They comply with the requirements of the European standards EN 10025-4:2004 for weldable fine grain structural steels and EN 10225:2009 for weldable structural steels for fixed offshore structures. They also comply with other national standards including ASTM A 913-11 and JIS G 3106:2008.

The figure below shows a comparison, based on yield strength, between HISTAR and other standard structural steel grades. HISTAR grades are compatible with the requirements of the Eurocodes for the design of steel structures and composite steel-concrete structures.

Super Jumbo Sections

Super Jumbo Sections

Super Jumbo Sections are proving to be a popular addition to the designer’s arsenal where low carbon equivalent values remove the need to pre-heat thick sections prior to welding, leading to additional cost and programme savings.

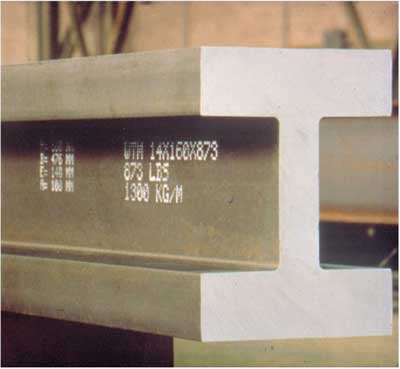

Super Jumbo Sections are very heavy rolled wide flange sections, with up to 140 mm flange thickness and weighing up to 1377 kg/m. They are available in ASTM A913 grades 485, 450 and 345 MPa, Histar 460, S460M and normal S355. An outstanding feature of Super Jumbo sections is their low CEV, allowing easier processing.

Environmental focus

ArcelorMittal reports an ever increasing focus on the sustainability of the products used in industries including construction, which is working to the advantage of steel over alternative products like concrete for building frames and bridges. Along with a host of other sustainability advantages that arise from selecting steel, developers and designers are eager to capitalize on the fact that steel has such a high recycled content.

Neil says: “Thanks to steel’s ability to recover its original properties without loss of quality after melting, steel is the most recycled material in the world.

“In the built environment, 99% of the hot-rolled steel sections can be re-used or recycled at their end of life. Being flexible and adaptable, the functional life of steel sections can be extended in refurbished and new constructions.

“As 100% of the recovered scrap will be used as a raw material in the steel industry, recycling contributes to resources savings and a better environment. “

Sustainable sourcing

Sustainable sourcing

ArcelorMittall Europe – Long Products has been certified under the BRE Environmental & Sustainability Standard BES 6001, demonstrating the company’s commitment to sustainable sourcing. This certification covers the entire portfolio of the Long Products division’s product range including angles, channels, merchant bars, rails, sections, sheet piles, rebar, construction bar and wire.

The certification is awarded following third party independent assessment that scrutinises organisational governance and supply chain management as well as environmental and social issues. Manufacturers also have to demonstrate the sustainable operations of raw materials suppliers.

Blue Book extension

Blue Book extension

An example of the support that ArcelorMittal offers to designers and steelwork contractors is the recent cooperation with the Steel Construction Institute aimed at helping them utilise the advantages of S460 steel. This resulted in a welcome extension to the Blue Book. Following the familiar Blue Book format, member capacities can be used for BS4 sections including the ArcelorMittal range of Jumbo Sections right up to 356 × 406 × 1299.