Technical

Strengthening existing steelwork

Dorota Koschmidder-Hatch of SCI describes the general principles of strengthening existing steel sections.

Strengthening implies the addition of structural material in order to achieve adequate stability, member resistance or stiffness. This may be achieved by adding material to increase load carrying capacity, stiffening the member or introducing additional restraint to the original section thereby increasing its overall resistance by reducing susceptibility to buckling.

The reuse of existing buildings contributes to the sustainable goals established by the UK government and strengthening techniques are fundamental to achieving this. In the light of the adoption of the Sustainable Construction Strategy it is preferable to refurbish an existing building rather than construct a new one. Adaptation of an existing structure saves the embodied energy of the structural elements, hence it is no surprise that BREEAM recognises the benefit of refurbishment as one of its building credits.

After the need for strengthening a structure is identified, the first step is to establish the intervention strategy, as described in Reference [1]. Alterations to historic buildings will need to address heritage concerns in line with the policies of relevant authorities (English Heritage in England). The general principles to be followed are the need to preserve as much original construction as possible, use of traditional materials and techniques and ensuring that the intervention is reversible as much as practically achievable. Where work is conducted in a building in use, the strategy needs to make allowance for user comfort and minimise disruption, for example in a working hospital limits on vibration and construction noise should be in place.

It is essential that adequate stability and resistance are maintained during the temporary stage when the unaltered structure is subject to actions at the time of strengthening and when the modified structure is subject to actions at the final design configuration. It may be necessary to relieve an existing section of some of its stress by propping or jacking before adding new elements. Care must be taken that such jacking does not overload the structure below.

New elements may be added to assist an existing one in resisting design actions. In such a case, some form of jacking and load transfer will be required. The designer needs to be aware that in some instances the addition of a new member changes the structural behaviour of the whole system. For example, introducing a tie to an unbraced arch leads to significant changes in stress distribution.

In a case where the new element provides a ‘safety factor’ to a ductile structure, it is necessary to provide a tight fit between the new and existing members. This ensures any ‘overload’ is transferred to the strengthening member.

There is also the option of supplementing the existing section with a new member, which allows retention of the original member without alteration and without risk of overloading. This approach is particularly useful in historic structures, as the process may be reversed, if necessary.

Examples of strengthening

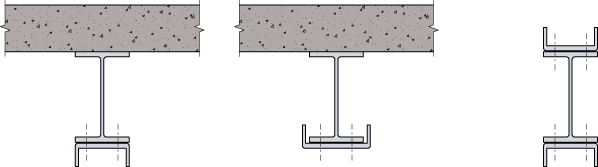

A common means of strengthening steel beams or columns is bolting on new steel sections (see Figure 1). If load sharing is required, it may be necessary to jack or prop the existing member and use preloaded bolts to avoid slip under loading. For old steel the use of spreader washers may be justified to avoid crushing when the bolts are tensioned.

Welding may also be used if the original material is weldable. A wide variety of steel sections such as plates, angles or bars may be added to the basic section profile (see Figure 2). Design of connections should allow flat or downhand welding as the work will involve welding on site. Propping may be required if the strengthening element is intended to take over some of the existing stress from the reinforced member via composite action. When a strengthening plate is expected to take a significant amount of stress, it may be worth continuing the reinforcement over the full length of the member. This approach eliminates the need to consider load transfer into the strengthening plate at its ends.

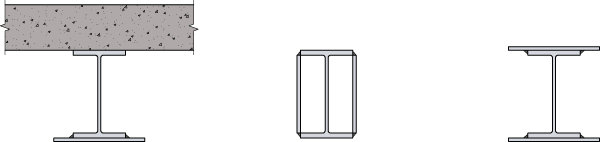

Where a grossly understrength beam needs to be retained, another beam may be inserted below or above it if possible. Preloaded bolts or welding may be used to ensure that composite action between the new and existing elements is achieved. Duplication of members is another way of relieving an understrength structure. For example, where for each existing beam a new parallel one is added, the loading on the existing beams is halved. This approach is suitable for historic structures, as it does not disturb the existing fabric, but it is difficult to achieve unobtrusively.

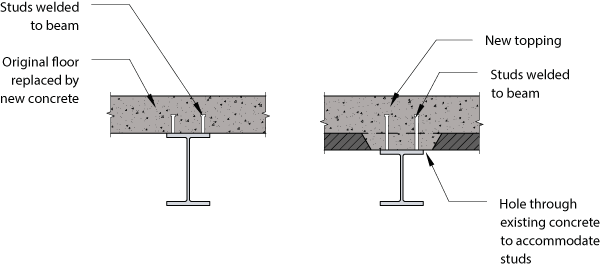

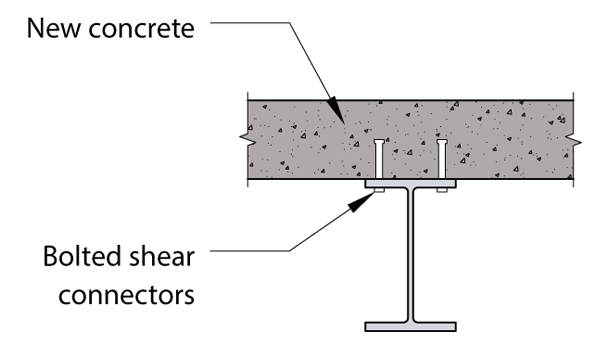

Strengthening a steel beam may also be achieved by adding shear connectors and providing either a new concrete slab or a new topping over an existing slab of weak concrete, as shown in Figure 3. In the latter case the existing concrete becomes permanent formwork for the new composite topping. If the steel is weldable, shear connectors can be welded to the beam, otherwise they could take the form of bolts introduced through the flanges, see Figure 4.

Concrete encasement is a popular strengthening or stiffening technique, when there are no objections to the original member being concealed. Concrete cover of at least 75 mm is recommended to provide room for reinforcement and adequate space for concrete to flow around the member. Good compaction of concrete is essential and may call for the use of external vibrators. Concrete encasement is also a means of providing fire protection to steel members. An example of concrete encasement is shown in Figure 5.

Strengthening hollow sections may be achieved by internal filling. This approach requires the introduction of openings for injection of concrete or grout and for the expulsion of air.

Connection methods

Methods for providing new connections and enhancing existing ones are considered here in the context of enhancing strength, stiffness or stability of existing structures.

The use of bolts is particularly convenient for site connections and where the connection is provided to an element made of non-weldable steel. Preloaded bolts can be used in joints where slip needs to be avoided, as described earlier. Alternatively, bolts in tight tolerance holes may be used where surface treatment required for preloaded bolt connection is not practical to achieve.

Many factors determine the success or failure of welding. Chemical composition, mechanical properties and the metallography of the original metal combined with the appropriate choice of welding parameters and procedure all influence the outcome of welding. ‘Weldability’ must always be tested.

Welding of stressed members requires additional careful consideration. Heat effects may cause loss of strength leading to yielding or buckling, therefore safety precautions must be in place. The use of clamped-on steel blocks acting as heat sinks may be implemented. Alternatively the welded member may be propped.

Designers need to bear in mind the practical limitations of welding on site, fire risk and the need to provide a controlled environment. Detailed design should call for vertical or downhand fillet welding, as they provide the simplest combination and are most likely to result in sound welds. Inspection and testing of welds is especially important in repair and strengthening work. If a suitable bolted connection is possible, welding is not normally preferred according to SCI [2]. Specialist advice on feasibility, welding materials, procedures and testing should be sought. SCI publication Guide to Site Welding [3] offers additional information on the subject.

The use of structural adhesives as an alternative method of joining structural elements is becoming more common. Bonded connections are typically achieved with the use of epoxy resin between steel or reinforced concrete beams or slabs and steel plates. This method provides a flexible form of strengthening where complicated connections are required and no additional heat or residual stress is introduced to elements joined. Adhesives are highly sensitive to elevated temperatures, their structural properties deteriorate over time and the lack of codified guidance for calculating structural resistance is a hindrance. The aerospace and marine industries have embraced the use of adhesive joints; performance data and structural properties are mentioned in Reference [4].

Conclusion

In a world where the drive towards lowering our carbon footprint is pushed by legislation, repair and strengthening are encouraged over demolition and building anew. In these circumstances developing knowledge of strengthening techniques for existing structures is a necessary step.

References

1. M Bussel, Appraisal of Existing Iron and Steel Structures, SCI, 1997

2. Design for Construction, SCI, 1997

3. P Craddock, Guide to Site Welding, SCI, 2002

4. S A Hashim, Adhesive bonding of thick steel adherends for marine structures, Marine Structures, volume 12, issue 6, 1999