Projects and Features

Streamlining steel distribution

Tata Steel is ramping up activity at its structural steel distribution site at Redcar, Teesside following the completion of the second phase of its redevelopment programme.

Tata Steel is ramping up activity at its structural steel distribution site at Redcar, following the completion of the Teesside Service Centre (TSC).

The TSC, which is situated next to Tata Steel’s Teesside Beam Mill, is the only steel sections processing facility in the UK backed up by adjacent production capability.

As well as providing customers with faster and more efficient delivery of steel sections, hollow sections and flat products, the recently completed facility will further reduce transportation costs.

Phase one of the development programme, which started in 2012, involved finding a home for this much larger stock holding. A single, specially designed site for Tata Steel’s UK sections distribution activities was established using an existing warehouse on the Redcar plant site.

The warehouse offers 15,000m² of premium storage space for the lighter sections and hollow sections. This is supplemented by outdoor stockyards (known as prairies) that cover nearly 40 acres and are used to store the other sections in the structural steelwork product range (nearly 200 sections), all of which are available in different steel grades.

This has created a modern stocking facility with the addition of new handling and processing equipment. The breadth and depth of the stock range now available ensures that Tata Steel is better placed to service customer enquiries.

Following the installation of the last of the new processing equipment due on site, the new facility is already looking beyond its nominal 170,000t per annum throughput capability in order to support customers’ increasing demand.

Director of the new facility, Tony O’Reilly comments: “The steel was previously transported to our Steelpark distribution centre in Wednesfield, and other service centres, before being transferred to the customer. This is now a much more efficient way of handling our steel sections that will speed up delivery for our customers. We can offer our customers an improved delivery service, with shorter lead times throughout the UK and Ireland.”

Phase two has involved the construction of a new office block for all of the TSC’s staff, the opening up of another warehouse and the installation of a high-specification shotblaster primer which is located in a 400m-long bay. This long facility allows multiple trucks to enter at one end for loading and drive through the bay and exit at the other end for dispatch. Phase two was completed with the installation of a new saw, capable of processing the largest of sections, whose outside location reduces handling time and costs.

TSC hosts five saws serviced by 13 cranes all designed with maximum operating and logistical flexibility to ensure timely dispatch of customer orders. TSC offers cutting-to-length and shotblasting, while a priming service means sections can come coated in the distinctive blue colour that distinguishes Tata Steel products throughout the market. The entire TSC operation is also fully compliant with all the new construction products regulations, including CE Marking.

Ian Beveridge, Director – Construction Structures Sector, says: “We have established the TSC so as to be able to offer customers a uniquely flexible service. The location at the end of a mill production line gives customers the option of buying ex-rolling or ex-stock. Besides, the investments we’ve made in logistics, handling and processing equipment means we’re able to offer a product and delivery service with unrivalled speed and efficiency. That all adds up to the TSC being a leading distribution facility in the UK and a benchmark in our industry.

“We stock an unrivalled range of structural steel products. Everything from beams, columns, parallel flange channels and hollow sections to wide flats and plate is available from TSC. Increased investment in our processing facilities has given us the ability to supply material to exact size, shape and specification, ready for immediate fabrication. We have expertise in assembling bespoke packages of structural steel ready for fabrication or delivery to site. And because we work closely with our customers we can optimise material usage and production cycles, thus cutting operating expenses and material waste.”

Sales and Marketing Director – Distribution, Paul Steele, adds: “Tata Steel is committed to investing in the future of its business and this scheme will provide significant cost-saving benefits, as well as ensuring the business is in an ideal position to meet the demand from our customers.”

Tata Steel has invested a total of £8.5M in TSC. Main markets served include the construction and building products sector, civil engineering and general fabrication. The facility complements other significant recent investments at both the Scunthorpe and Teesside sites, including the current £52M project to reline the Queen Anne blast furnace in Scunthorpe to support increased production of long products.

A net total of around 40 new jobs have been created as a result of the establishment of TSC, which employs 94 people in all.

Teesside Beam Mill

Teesside Beam Mill

As the only steel sections processing facility in the UK backed up by adjacent production capability, Tata Steel is able to support its customers with reduced lead times and increased stock availability as the mill routinely rolls to stock on a 48 hour basis and produces rolled-to-order sections to within 100mm increments of length.

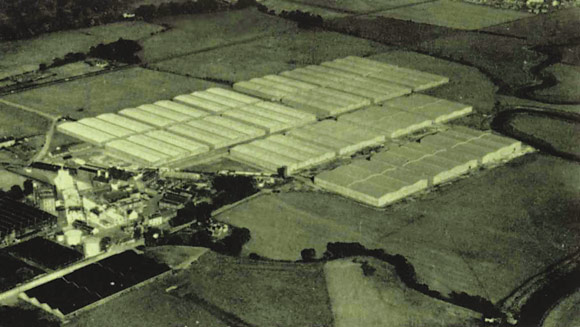

The Prairie

The Prairie

The prairie holds the facility’s stock of heavy sections. The immense area available allows Tata Steel to hold one of the most comprehensive ranges of stock in the market, ensuring it is able to support customer enquiries.

Consolidating distribution activities onto a single site adjacent to the mill means that it is able to reduce unnecessary transport between facilities and operate extremely efficiently.

Shotblaster Primer

Shotblaster Primer

Shotblasting is one of the services Tata Steel is able to provide to its customers. Sections can be prepared for fabrication through sawing (cut-to-length and mitring) as well as shotblasted and primed.

The site’s new shotblaster-primer utilises water-based coating systems and the latest control equipment to ensure minimised environmental impact and the best product surface quality. Its high-speed throughput and capacity ensures Tata Steel is able to respond to customer demands.

Warehouse

Warehouse

The large warehouse provides the perfect indoor storage facility for light sections and hollow sections. The vast space ensures Tata Steel is able to stock one of the widest ranges of products available and that they always reach the customer in optimum condition.

Shotblasted and primed sections

Shotblasted and primed sections

Finished sections ready for despatch in the distinctive blue shade that reinforces Tata Steel’s product and processing traceability from a CE Marked producer.

Watch the video…