50 & 20 Years Ago

Spic and span on Severn Bridge

Without maintenance few things can last. This is as true for bridges as for, say, a car. The County Surveyor’s Department of Gloucestershire County Council is responsible for looking after the Severn Bridge and some aspects of this work are described in these notes by Mr Sydney Brown, a Deputy Surveyor.

The maintenance of steel bridges has always presented problems – some not adequately realised at the design stage so that, for instance, insufficient thought has been given to accessibility for the renovation of protective coatings.

In the early days of fabrication hot rolled sections were more prone to lamination and the ingress of moisture through coatings which had deteriorated because of inaccessibility or neglect accelerated this. Most of the early problems persist and others are inherent with present-day developments in design made possible by the production of high-quality steels and these call for a more thorough approach to maintenance, particularly in regard to large cellular bridge units in which thin stiffened plates, which have no margin for corrosion, are used.

The Severn Bridge complex is a case in point. Four structures are involved extending over a continuous length of almost two miles and having a total deck width of approximately 100ft.

The shortest of the structures, the Aust Viaduct, bridges over the foreshore from the Aust Cliff to the Severn Suspension Bridge south anchorage, a distance of 200yds; it has three spans with two longitudinal continuous box girders, 10ft deep by 7ft wide.

The three major structures have a single 10ft deep longitudinal welded box girder with cantilevered wings; the box is 75ft wide on the Suspension Bridge and reduces to 55ft on the Beachley Viaduct and cable-stayed Wye Bridge; the cantilevered wings on the latter are accordingly wider to give the same total width of decking.

The floors and sloping webs of the single box sections are of 3/8in thick plates stiffened with bulb flats except in the vicinity of trestle supports where the thickness of the plates is increased; the trough stiffened plate decking on which the carriageway surfacing is laid is 7/16 in thick. There are approximately 600 miles of welded joints.

Prior to fabrication of the box girder units the external surfaces of the plate panels were grit blasted and metal sprayed (using zinc or aluminium) and a protective paint system consisting of one coat of etch primer, two coats of zinc chromate, and two coats of micaceous iron oxide was completed on erection of the girders.

The structures are exposed to high winds, salt-laden atmosphere and sulphur fumes carried on the prevailing wind from chemical works at Avonmouth.

The interior surfaces of the boxes carried heavy condensation at the time. construction of the complex was completed.

Gloucestershire County Council as agents of the (then) Ministry of Transport accepted responsibility for the maintenance of the structures when the complex was opened in 1966. Some involvement whilst construction was in hand had enabled the county to appreciate the immensity of the problems and accordingly an organisation was set up having three experienced inspectors as its nucleus. The senior inspector had been staff foreman with the consortium of contractors who had built the structures; one assistant, a skilled welder, had organised welding of the deck units at Messrs Fairfield Mabey’s shipyard and the third had been an inspector concerned with workmanship on the Wye Bridge contract.

A schedule of operations was programmed and this covers examination of every part of the structures at the frequencies considered necessary. At the extremes, deck expansion joints are examined weekly, and on the Severn Bridge the main suspension cables and clamps from which the suspenders hang are inspected annually. Crash barriers are under almost continuous surveillance by the maintenance teams in their journeyings to the locations where they are working. Certain inspections are seasonal, as, for instance, the inside of the Severn Bridge towers and anchorages where work is confined to the winter or periods of stormy weather. The schedule allows some latitude for unforeseen problems arising, but diaries are kept so that, in the whole year, the programme is effectively adhered to.

To facilitate operations, each part of the structures has a reference code and number for easy identification on site and in the maintenance record system. The references are stencilled on the units on site and are shown on key plans displayed in the office; on the latter are indicated each day the locations at which operations are in hand.

Each 60ft long deck (box girder) section as fabricated for site erection is a referenced unit; for instance on the Severn Bridge the 10th deck unit from the Aust tower in the Aust side span bears the reference AS10. On the Aust tower the 5th section up from the base on the downstream leg has the reference AT5D. All suspenders and cable clamps are referenced in association with the deck units they carry.

A record card is kept for each unit and on this is noted the dates upon which inspections are made; also on it are instructions regarding points which should be observed, and where necessary a photograph is attached. Inspection sheets kept in date order record instructions given for renovation or repair and also of the work carried out; persistent faults can thus be identified.

When inspection operations commenced late in 1966, it was evident that renovation of certain areas on the underside of the wide boxes should be put in hand as soon as possible, for zinc oxide was erupting through the protective coatings. It was mainly on the units which had been kept overlong in the River Wye before being towed out for hoisting into position on the Severn Bridge. Bulb flat stiffeners on the underside of the cantilevered wings were also affected due to contamination held in condensation. Rusting was breaking through along the unsealed edges of the weld backing flats. Inside the wide box girders condensation was causing mill scale to strip and rusting was developing.

To deal urgently with the deterioration of the coatings on the external surfaces, two teams of three men who had worked as riggers on the construction of the bridges were engaged and trained in the use of grit blasting and airless spray painting equipment.

The problem of condensation inside the girders called for some investigation on the part of the consultants Freeman Fox & Partners and the firm of Joseph Crosfield. It was decided that silica gel should be placed inside the structures as an experiment in an attempt to combat this, for renovation of the paintwork could not in any case be carried out unless the surfaces were clean and dry. Accordingly silica gel provided in 10 lb bags was installed at a concentration of 1 lb per 80 cubic ft of internal volume.

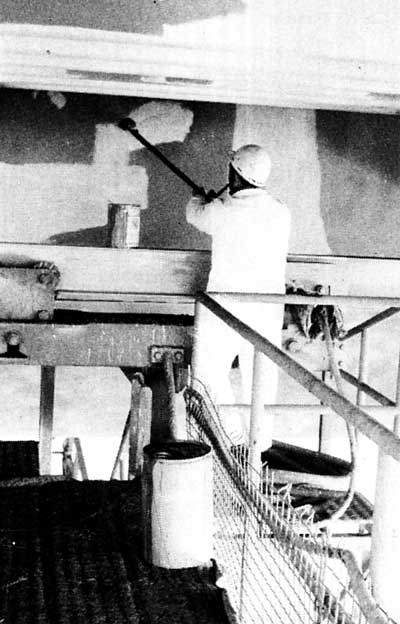

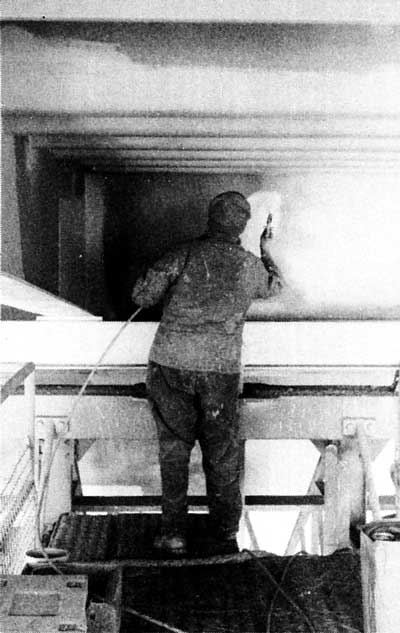

Renovation of the external protective coatings is now an established routine. Dealing with one deck unit (a 60ft length of decking 100ft wide) the procedure is to grit blast a 10 ft length of the underside of the box (normally a morning’s work) and to cover this with one coat of zinc chromate by roller before the end of the working day. The grit blasting is carried out to a greater or lesser degree according to the condition of the coating; with a heavy concentration of zinc oxide pustules breaking through the coatings or where rust is developing.The blasting cleans down to the surface of the steel; if the coatings are breaking down but with no sign of zinc oxide the coats of paint alone are removed and where the paint is in fair condition it is given a ‘flash’ blast which cleans and etches the surface to make it receptive to the application of further coats of paint. Repeating the operations described above, at the end of six working days the cleaning process and the application of a single coat of zinc oxide is completed on one deck’ unit. Airless spray painting equipment is then used to apply three further coats of paint, one of zinc chromate and two of micaceous iron oxide over the whole area and these operations take a further 1½ days. Thus one deck unit is completely renovated in a period of 7½ days. This procedure is adopted because it is not worth while setting up airless spray painting equipment to coat a 10ft length of decking which must however be covered within four hours of cleaning or rusting will develop.

The use of silica gel to eliminate condensation inside the boxes has proved a success for although, at first, most of it required replacing after twelve months (at a cost of about £4,000) this was partly because of the high degree of condensation in the boxes at that time, and also because there were leakages in the airtightness of the structures allowing excessive breathing. The structures, now divided into fourteen sealed sections, leak so little that replacement of the silica gel is only necessary every three years and renovation is not required. Thus the number of operatives on the complex is kept to a minimum and health hazards to men engaged in painting in confined conditions are avoided. The airtightness causes pressures to build up with rising temperatures and these are monitored. The condition of the silica gel in each section can be observed through a small window where a 10 lb bag of silica gel placed on a balance can be seen; when the scale shows the gel to have taken up 3 Ib of water the gel is saturated and needs to be replaced.

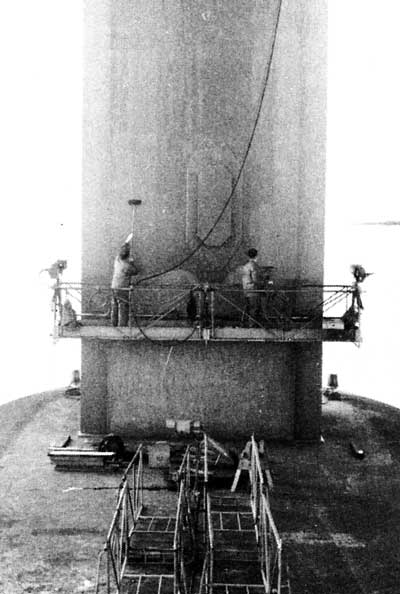

Most of the maintenance work has to be done from gantries or stagings. Gantries were in position on the Severn Bridge spans before the structures were completed and these extending the full width of the decking are suspended from the edges of the cantilevered wings.

Gantries for the Aust Viaduct, the Wye Bridge and Beachley Viaduct have been designed by Gloucestershire County Council, as have also gantries in the Severn Bridge anchorages and a carriage which runs on the main suspension cables.

The Aust Viaduct gantry runs between the two longitudinal box girders and has a retractable lower platform from which the underside and outer webs of the box girders can be treated.

The Wye Bridge and Beachley Viaduct gantry is in two halves and each runs on a single rail attached to the underside of the cantilevered girders extending from each side of the wide box girders. Each has a retractable lower platform from which half of the underside of the box can receive attention.

In the Severn Bridge anchorages, the gantries provide for the suspension of cages from which the steeply sloping splayed strands of the main cable can be cleaned and coated.

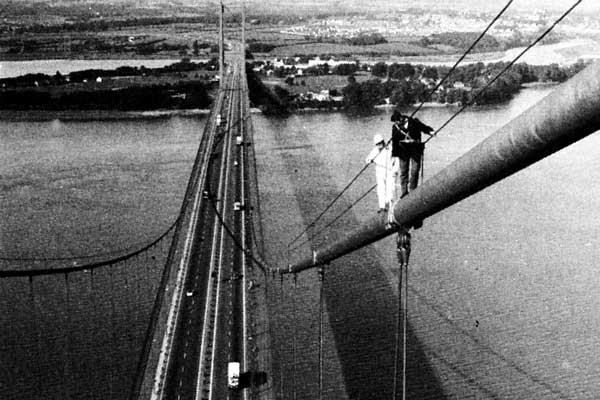

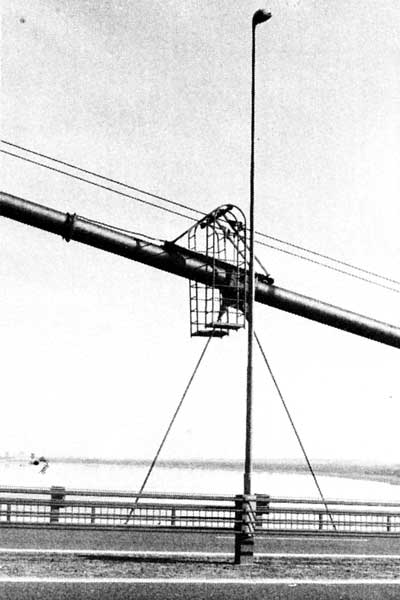

The carriage on the main suspension cables has two cages which hang vertically, one on each side of the cable so that operators can sit one in each cage to renovate the cable or check accurately the lengths of the ten high strength bolts in each clamp from which the suspenders hang; the length of each of the no. 1760 bolts was measured with a large micrometer, after final tightening and recording; the same micrometer is used for checking. The carriage is winched along the cables by means of a tirfor.

The high degree of inspection on these structures is shown to be justified not only by the standard of maintenance which is being achieved with protective coatings, but also in the timely detection and rectification of faults, such as:

(a) Strand slip on the cable-stayed Wye Bridge anchorages necessitating modification of the strand couplings and resocketing (work carried out on site by British Ropes Ltd).

(b) Ineffective performance of the liquid springs cushioning the plates of main carriageway expansion joints at the Severn Bridge towers (modifications carried out by the maintenance staff).

(c) The appearance of weld cracks (repairs carried out under the direction of the welding inspector).