50 & 20 Years Ago

ERF Service Centre

Middlewich is in an area subject to severe settlement caused by the salt workings. This Sevice Building had to be designed to accept the settlement therefore and the solution to the problems this presented are outlined in this article by Mr J.E.C. Farebrother of the consulting engineers.

The new Service Building for Messrs E.R.F. Limited, who manufacture heavy commercial vehicles, is located at Middlewich, Cheshire, approximately four miles from the company’s main office and works at Sandbach. The Middlewich area is subject to settlement from brine pumping. The operation of brine pumping causes runs to form which can cause severe settlement within the area of the run. It is impossible to say where or when a run is likely to form or indeed if a run will be formed at all. After carefully considering all factors, it was decided it would be prudent to take reasonable precautions within the building on the assumption that a run may form under any part of the building. The degree of settlement likely is difficult to predict, but if settlement did occur it would in all probability, occur in a narrow band. Settlement, if it takes place, is likely to be in the order of 9in in twelve months.

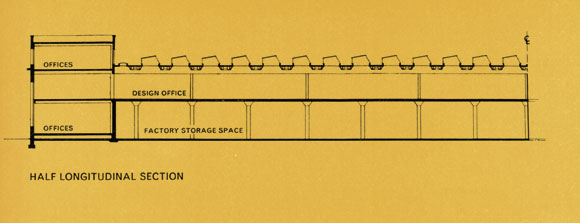

The building complex consists of three main areas:

- The service/store bays, consisting of two 230ft long bays each of 100ft span, with provision for extension at the gable end of the building. Each bay is designed to carry two cranes of 2-ton or 5-ton capacity without intermediate supports.

- The ancillary area, including lubrication bays, etc.

- The office block and administration area.

The site contained a number of old bases, pits and brine-settlement tanks which had to be removed before construction could start. A number of trial pits were dug and indicated 4ft of firm clay below the top soil. Water-bearing sand was found below the clay.

The office block is located partly over the old brine-settlement tank foundation, but luckily the majority of the other obstructions were away from the main stanchion foundations.

After considering the implications of the possibility of brine settlement and the ground conditions the following decisions were made:-

- To design the structure of the main service area to accommodate differential settlements of 9in in 100ft with provision for jacking the stanchions back to their original posItIon.

- To hang the crane rails from the underside of the main roof trusses.

- To drain the roof to both sides of the building away from the central support, to reduce the problem of backfall should settlement take place. Sufficient fall to be provided to accommodate likely settlement.

- To found the main building foundation within the clay strata to avoid problems associated with building in water-bearing sand.

Foundations to the service area were designed as isolated bases with the stanchion base-plates supported on plinths above ground-floor level, to facilitate access to the holding-down bolts for adjustment and jacking.

The ancillary buildings and office block were built on partial raft foundations of a fairly simple type capable of spanning 25ft or cantilevering 15ft should settlement occur.

Galbestos cladding was decided upon for walls and roof. It was known that sheeting at a salt works approximately half a mile from the site had corroded badly due to salt in the atmosphere, but in view of the distance of the new site from the works and the direction of the prevailing wind it was decided that the intensity of salt would not be sufficient to cause trouble.

Eight-foot-high brick impact walls are carried on mass strip foundations between the main stanchion bases with expansion joints at each of the main stanchion positions and brick reinforcement in the top course to reduce the amount of damage likely to occur if settlement takes place.

In view of the very short contract time, it was decided to use a steel frame throughout with precast floors to the office block and to the mezzanine floor of the service area.

A number of inspection pits were required within the service area. These were built of reinforced concrete to CP 2007 in view of the ground water conditions.

The ground slab within the stores area was designed as a series of adjacent road slabs having longitudinal fabric with dowell bars connecting one strip to the next. Alternate strips were cast first followed by the intermediate strips which were screeded off smooth to facilitate the use of stackertrucks. The same system could not be used within the service area owing to the layout of the pits. The slab was therefore cast in the normal way using a square fabric.

Main service and stores building

The main roof members have been designed as lattice girders with a fall from the centre row of stanchions to the outside. The girders have been designed to carry two 2-ton or 5-ton cranes. The position can be varied on the truss providing they are picked up at the node points. Cranes have only been installed in the service area at present.

In order to allow for differential movement, all connections are articulated, except for the feet of the central stanchions, which have been fixed. A similar provision has been made longitudinally, except that two stanchions have been linked together on one base to provide a strong point to which the other members are linked. Rubber bridge bearing pads have been incorporated at each of the pin joints to allow for the anticipated rotation.

In the event of subsidence taking place, those stanchions which have settled will be jacked back to level on the extended bolts provided. If settlement of the fixed points occurs these will be jacked level and re-plumbed.

Some superficial damage may occur to the horizontal diagonal bracing during settlement, but the cost of replacement of the damaged members will be negligible compared with the cost of incorporating a complex arrangement to accommodate the movement. Settlement will be slow and is most likely to show up in the first instance through difficulties in operating the cranes. The cost of providing the precautions mentioned above was estimated to be approximately 5 per cent of the cost of the frame.

Offices

The offices are of two-storey-high construction with provision for a further storey to be added later. In view of the very short contract period, it was decided to use a steel frame with precast concrete floor units. A brick construction was required. It was decided to carry the building on a raft foundation. In order to reduce the effects of settlement, the building has been split into four units by 2in wide expansion joints and the foundations to each section have been designed as an independent raft.

Part of the foundations have been carried on to the existing brine settlement tank floor. As this slab had carried approximately 1 Oft of slurry for a number of years, it was considered that it should be capable of carrying the load from spread foundations. The edge of the tank determined the first expansion joint due to the risk of differential settlement.

General

The building which was opened by the Minister of Transport, in November 1971, used 420 tons of structural and 90 tons high tensile and mild steel reinforcement. The total value of the contract was £420,000, and the whole of the project was designed and built in twelve months, from receipt of clients instructions. The actual work on site took nine months.

Architect: Messrs Mason and Richards & Partners

Consulting Engineer: Messrs J. E. C. Farebrother & Partners

General Contractor: Messrs S. W. Clarke (Contractors) Limited

Steelwork Supplier: Messrs Wilfred Robbins Limited

Rubber bearing pads supplied by: Messrs P.S.C. Equipment Limited