Projects and Features

Digital expansion

Cumbrian IT and digital technology companies are set to get a significant boost when the steel-framed Workington Innovation Centre opens its doors.

FACT FILE

Innovation Centre, Workington

Main client: Cumberland Council

Architect: Buttress Architects

Main contractor: Morgan Sindall Construction

Structural engineer: Mott MacDonald

Steelwork contractor: Leach Structural Steelwork

Steel tonnage: 180t

Big changes are afoot in Workington, as more than £30 million of investment is helping to transform and regenerate West Cumbria’s largest town.

Government funding, via the local Town Deal, is supporting a number of priority projects, one of which is the Innovation Centre, that will create an economic boost by providing accommodation for local businesses.

Leader of Cumberland Council, Councillor Mark Fryer, explains: “The building will provide entrepreneurial support and high-quality office accommodation. It will transform the town centre and help to increase footfall, which is great news for the local economy.”

Located on a town centre plot, once occupied by a car park, the Innovation Centre will primarily be aimed at digital technology and advanced manufacturing businesses. The aim is to attract start-ups who are ripe for incubation, as well as small businesses ready for growth. Experts will be available to help them achieve their ambitions.

The long term aim of the project is to contribute to the growth and retention of SMEs within Workington and West Cumbria, generating an uplift in innovation activity throughout the area.

John Coughlan, the Chairman of the Workington Town Deal Board, said: “The Innovation Centre will be transformational for Workington. Attracting high-quality start-ups will lead to a growth in advanced manufacturing and technology jobs. We are now seeing the real value of the work which secured funding for Workington and the greater region.”

The four-storey, steel-framed building will contain private and informal meeting rooms, conference spaces, and catering facilities. Sustainability is key to the design, so cycle storage and shower facilities will be provided to encourage tenants to use green methods of transport.

Measuring 22.5m-long × 22.5m-wide, the square-shaped building is 16.5m in height from ground floor to top of parapet.

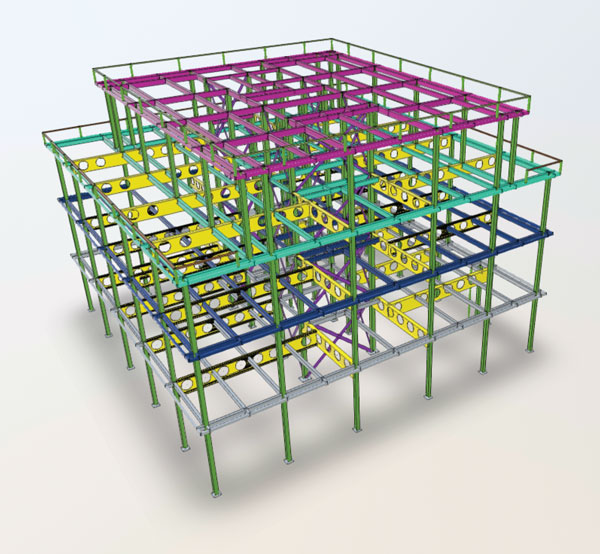

The building’s design is arranged around a centrally-positioned concrete core, which along with its vertical bracing, provides stability to the steel frame.

An 8.5m × 4.5m column grid arrangement will provide maximum flexibility within the office floor plates, allowing partition walls to be removed or installed, with no hindrance from internal columns.

The primary beams are all Westok cellular sections, chosen for their lightweight attributes and service integration. Bespoke openings in the beams accommodate the buildings services within their depth.

First floor beams are 900mm-deep members with 625mm-diameter openings, while the upper floors have either 791mm-deep or 765mm-deep cellular sections with 550mm-diameter cells. Throughout the building, the secondary beams are shallower than the primary members, allowing the services to run underneath them.

“The key service routes on this scheme were through the lightweight clear-span primary beams,” comments ASD Westok Design Team Manager John Callanan. “We worked closely with the engineers to detail the cell openings accordingly.”

The primary cellular beams, which weigh up to 2t each, typically span from the perimeter columns to the core. They help support the composite flooring solution that consists of metal decking and a concrete topping.

According to Mott MacDonald, the project’s structural engineer, a metal decked solution was chosen to gain maximum design efficiency for the floor structure through its composite action.

A typical column grid consists of 130mm concrete slab on a composite metal deck that spans approximately 2.5m onto secondary beams, which in turn span onto the primary beams.

Composite floor slabs act as rigid diaphragms, transferring loads from the perimeter cladding back to the core and its bracing elements.

As well as providing the project’s required flexibility, a steel-framed solution was chosen for its ease and speed of construction.

Working on behalf of main contractor Morgan Sindall Construction, Leach Structural Steelwork erected the entire steel frame in four weeks, using a single 80t-capacity mobile crane.

Fully glazed elevations are an essential part of the design. To fulfil this brief and maintain the desired unobstructed views from the building, there no vertical bracings between perimeter columns.

“The lack of bracing generated stability issues within the steel frame during the erection programme. This required a collaborative planning approach between ourselves and Morgan Sindall,” says Leach Structural Steelwork Project Manager Karl Hunter.

“The solution was to begin the steel frame erection around the central core area, working our way outwards towards the perimeters. This method ensured the stability of the steelwork in both its temporary and permanent conditions.”

Creating a distinctive architectural feature, the ground floor is partially recessed along the north and west elevations, creating a first-floor overhang above the main entrance way.

Forming this 1.2m-deep cantilever, the columns at ground floor level are set-back.

Meanwhile, at third floor level, a number of beams act as transfer elements, carrying the load from roof level to the core and perimeter columns, due to the floor being inset along the north, south and west elevations.

The completed four-storey building will be clad in metallic panels with full-height windows, providing plenty of natural light without losing energy efficiency. Air source heat pumps will be installed, while solar panels on the roof will help meet the building’s electricity needs.

The Workington Innovation Centre is due to be complete in early 2026.