Technical

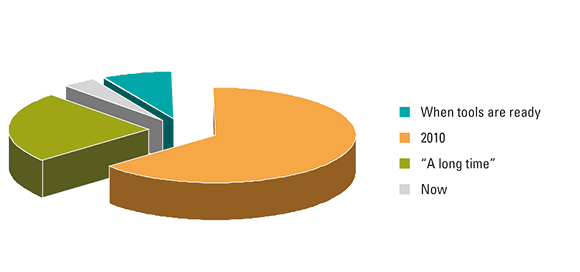

Countdown to Eurocode Implementation

New European Fabrication Standard

EN 1090-2 is the European standard for the fabrication and erection of structural steelwork – or “execution” as it is now termed. Although not a Eurocode it is part of the suite of European standards for the design, fabrication and erection of steel structures. This standard was recently approved by Member States and it is anticipated that it will come in to force in June 2008. Unlike the Eurocodes there is no overlap period and when it comes in to force it will immediately replace current national standards such as BS 5950-2 and BS5400-6.

The scope of EN 1090-2 is much wider that the individual national standards for execution of steelwork as it covers buildings, bridges, towers and masts and most other land-based steel structures. EN 1090-2 is closely linked to the CE Marking requirements for steel structures and components which are given in its sister standard EN 1090-1 which has recently been circulated to Member states for Formal Vote.

Fabrication of Structural Steelwork

At the centre of both the new European execution standard and CE Marking is a concept with which most Steelwork Contractors and designers will not be familiar. This is Execution Class (EXC). The Execution Class defines the level of assurance and workmanship to be applied to different structures or the manufacture of components. The concept is also referenced in manufacturing standards for aluminium and precast concrete components. In EN 1090-2 the informative annex on Execution Class recommends different levels of traceability, welding quality management and weld acceptance criteria. It lists four execution classes from EXC 4 which is the highest required level of assurance to EXC 1 which is the lowest. The Execution Class can apply to the whole structure but it can also apply to individual details. For example a structure could be classified as EXC 2 but a particular detail (e.g., a detail subject to fatigue) could be classified as EXC 3. EXC 2 is the default class, and in broad terms the Execution Classes can be viewed as follows:

- EXC 1 – Farm buildings

- EXC 2 – Buildings (similar to the scope of the NSSS)

- EXC 3 – Bridges (and other structures with fatigue)

- EXC 4 – Special structures (long-span bridges, power stations)

The Execution Class is a client decision and will need to form part of the specification. Furthermore, CE Marking requires the Steelwork Contractor to have in place a certified the Factory Production Control (FPC) system (similar to ISO 9001) against his chosen Execution Class. Each Steelwork Contractor, therefore, needs to choose carefully the Execution Class to be included in his scope of registration. If it decides to choose EXC 2 (say, Buildings) it would not be able to CE mark structures or parts of a structure that are classified as EXC 3 or higher. Designers will also need to be aware of the limits on Execution Class particularly when associated with CE Marking.

Essential and Functional Tolerances

EN 1090-2 also gives a list of fabrication and erection tolerances many of which will be familiar to designers as they as similar to those given in our national standards. But unlike our national standards the tolerances in EN 1090-2 are split in to ‘Essential tolerances’ and ‘Functional tolerances’. Both would be mandatory if invoked under a contract specification but the Essential tolerances are linked to the design assumption on structural stability given in Eurocode 3 and are relevant to the public safety requirements included in CE Marking. Thus the tolerance characteristics for CE Marking relate only to the Essential tolerances.

Welding Quality Management

EN 1090-2 also introduces in a more formal way the Welding Quality Management (WQM) system and the Responsible Welding Coordinator (RWC). The type of WQM system required and the knowledge and competence of the Responsible Welding Coordinator are themselves linked to Execution Class and the range of materials and welding processes carried out by the Steelwork Contractor. Like the National Structural Steelwork Specification, EN 1090-2 does not require the Steelwork Contractor to have in place a certified WQM system only that the WQM systems complies with the relevant part of BS EN 3834. However, the requirements for CE Marking given in EN 1090-1 do require the Steelwork Contractor to have the system certified.

Steelwork Fabrication – A Manufacturing Process

Another significant difference is that EN1090-2 places more responsibility on the Steelwork Contractor to get it right first time. The requirements are firstly to prove that a welding process can be implemented in production after which the amount of testing can be reduced. However, should a non-conformance be found the steelwork contractor must carry out additional tests to identify the cause of the problem and to change the process so that the problem does not recur.

Additional Guidance

Some of the concepts introduced in EN 1090-2 will be unfamiliar to designers and therefore the British Constructional Steelwork Association is producing additional guidance for buildings and bridges to ensure that UK specifiers and designers can use the standard safely. In particular an updated version of BCSA’s National Structural Steelwork Specification will be issued for buildings.