50 & 20 Years Ago

Catalogued Car Centre

Previous articles and one issue of Building with Steel (No. 6, Feb 1971) have shown how proprietary systems of construction can be adapted to many types of building. The car showroom and filling station featured in this article again demonstrate the flexibility possible within a catalogued system – this time Stran-Steel – which is well established in North America and now being increasingly employed in the UK.

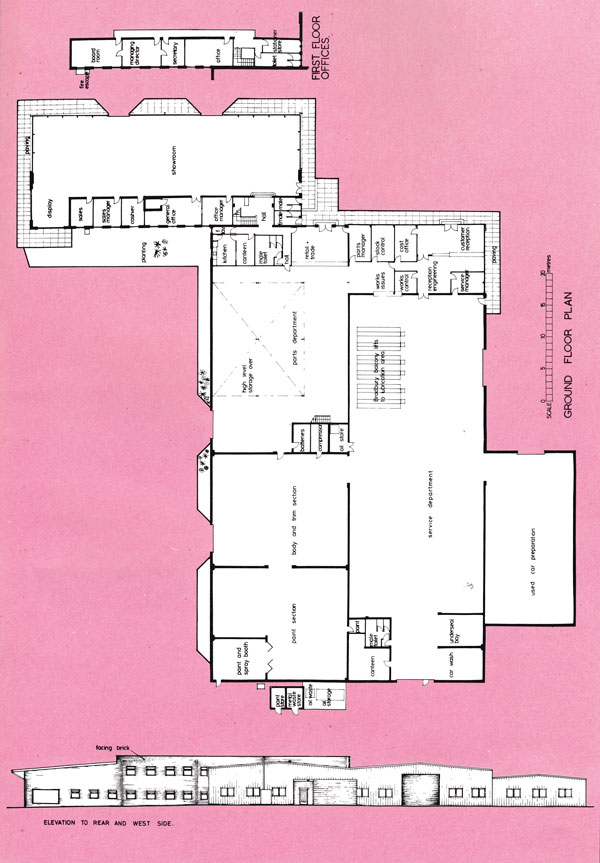

New premises for The Cleveland Car Company Ltd, built on a triangular site bounded by Croft Road and Bridge Road at Blackwell Corner, Darlington, Co. Durham, comprise a petrol filling station, Autorama, pump house, works department, offices, motorcar showroom and ancillary buildings.

The site is covered by two Authorities, the County Borough and Darlington Rural District Council, and in order to comply with planning requirements the vehicular access to Bridge Road (A66) had to be closed and the new access and exit on Croft Road (A 187) completed before demolition commenced.

Site works included demolition of existing buildings, removing all hedges and trees, grubbing up old foundations, paths, concrete areas, old drains and a septic tank, to clear the site completely. Sufficient top soil then had to be spread over areas scheduled to be landscaped in due course with new trees and shrubs.

Concrete foundations were prepared for the new buildings, particular care being paid to the level of the workshop floor, and the showroom area where the level had to be built up. Extra excavation was required along the Croft Road boundary, where the levels of the land are low and additional subbase material was required to fill on to a solid bottom. Forecourt areas, including the Autorama, under canopies, etc, were finished with tarmac.

Once the foundations were complete, the major part of the construction was carried out by Allerton Industries Ltd. Just over three years ago, Allerton Industries widened the scope of their steel fabrication by acquiring the licence to manufacture the Stran-Steel range of pre-engineered steelframed metal-clad buildings, and they are sole UK manufacturers.

The erection of The Cleveland Car Company development followed the usual Stran-Steel pattern, meetings taking place at an early stage between engineers from Allerton’s Stran-Steel Division and the architect.

Standardization of the Stran-Steel system means that agreement can be reached quickly on building dimensions and other standard features such as roof extensions, canopies, windows and doors, used in conjunction with Stran-Steel colour-coated cladding. When the primary decisions have been made, manufacture of the components in the factory progresses concurrently with the preparation of the site, thus saving time and money.

All the structures for the Cleveland development were of steel-framed construction, the main frames being plate-fabricated, jig-built at Stran-Steel’s Northallerton Works. For the secondary members, extensive use was made of cold rolled sections. These two factors combine to give a building system with a high strength to weight ratio. Tapered rafter and column sections are designed to provide a pleasing visual appearance.

The standard Stran-Steel system offers a range of building spans and eaves heights, and building accessories specially designed for use with this type of building, including sliding windows, doors, ventilators, etc. Allerton Industries design, supply, deliver and erect complete building superstructures, including supplying and fixing all cladding materials, various types of insulation and building accessories. A chain of franchised builders throughout the country offer a complete building service with the Stran-Steel system in conjunction with Allerton Industries Ltd.

The standard building units used for the Cleveland complex were a double 60ft span x 16ft eaves x 200ft long StranMaster unit for the main workshop and stores area, a 40ft span x 12ft eaves x 75ft long Stran-Master unit for the used car preparation building, and a 120ft span x 16ft eaves x 50ft long low roof unit for the motor-car showroom. A mezzanine floor for storage and runway systems for parts handling and maintenance purposes was constructed over part of the workshop area, with access from a metal staircase.

Cladding materials used were from the standard range of Stran-Steel colourcoated panels, Stran rib profile being used on the roofs and Stran architectural profile panels for the side and end walls. Plasticfaced insulation was fixed in conjunction with the cladding panels to all sheeted areas. The roofs were extended at the ends of the building, using standard 3ft 6in and 1 ft 6in extensions with white colour-coated steel soffits. Standard horizontal sliding windows and standard plastic coated steel personnel doors were incorporated in the side and end walls. Steel roller shutter doors give access to the sales and service areas. The front and sides of the motor-car showroom are glazed and incorporate glazed sliding-door units.

The floor of the motor-car showroom is of 3mm Forester Green Speckled Plasik polyester resin on a cement and sand, screed over a Treetol dpc membrane.

Roofs are insulated with ¾in thick plasterboard, Plastic faced and foil backed, fixed over purlins. A total of 96 glass-fibre reinforced polyester rooflight panels were fixed over the workshop area.

Work on the petrol filling station included the provision of a kiosk, night watchman’s building, pump island, concrete apron, tanker unloading bay and underground petrol storage tanks. Other facilities provided in the complex include a kitchen, canteen, and staff and public toilets.

The Cleveland complex is situated in an area of considerable natural beauty, with a heavily wooded area on one side of the site and open countryside on the other. The colour chosen for the steel cladding in this case was therefore Mist Green (Stran Satin). Roofs are finished in white (Vinyl Stran Satin 262). For this contract a small amount of stonework and brickwork was introduced in the external finishes. Stonework cladding has been used at the rear of the showroom where the wall faces the forecourt. Facing brickwork has been used to the rear wall of the showroom building, where the first-floor office suite has been constructed.

Wooden windows and reinforced concrete lintels to door and window openings have been used in conjunction with the brickwork and stonework instead of the standard Stran-Steel metal components used elsewhere.

Flat roofs were specified over the first-floor office construction, the metal waste store, the kiosk and the night watchman’s building, finished with ¾in limestone chips over 3-ply built-up Ruberoid roofing felt over chipboard and glass-fibre insulation over joists. Two Cordar pvc skydomes have been fitted over the staircase and the office area.

First-floor office areas are covered with Burmatex non-woven nylon carpet laid on chipboard. Other floors in public and office staff areas are finished with vinyl asbestos tiles.

Walls of the board room and the managing director’s office are decorated with vinyl wallpaper. Walls and ceilings of other areas generally are finished with emulsion, gloss or eggshell paint.

Suspended ceilings have been installed in the motor-car showroom and in the board room; with 4ft x 2ft Celotex FRI flameresistant boards in the showroom and 12in x 12in Treetex Glacier acoustic tiles with concealed suspension in the board room.

Other ceilings throughout are constructed with 1in ICI purlboard, polyurethane rigid foam laminate, K value 0·16.

Central heating is by warm blown air feed to all areas in the building from four Powrmatic oil-fired boilers.

The site is enclosed by a 6ft high close boarded boundary fence. Corrall-type fencing has been erected round the oil and metal waste stores areas.

Stran-Steel’s contract included the design, supply and erection of all primary and secondary steelwork, wall and roof cladding, insulation, rainwater goods and all other building accessories, together with internal catwalks, platforms and walkways for storage purposes.

The external canopies and used car Autorama were specially fabricated by Allertons to suit the architect’s design.

The building was erected last year over a period of six months.