Technical

AD 489: Height of shear studs

AD 380 entitled “What height of shear stud should be used in Eurocode 4?” provided interim advice on the height/length of shear studs to be used in design calculations and referred to a programme of tests/analysis that was in progress. On completion, the programme of tests provided the input to SCI publication P4051 but AD380 was not subsequently updated. This AD note now supersedes AD380 and reconfirms and supplements the guidance it contained.

BS EN 1994-1-12 defines hsc as the ‘overall nominal height’ of a stud connector in the list of notation, but elsewhere the same variable is defined as simply ‘the overall height’. Moreover, a stud that is for example 105 mm long when manufactured would typically have “length after welding” (LAW) of 100 mm when welded directly to a beam flange, or 95 mm when welded through decking. It would generally be described as a nominal 100 mm stud.

Resistances

Stud resistance values are a function of hsc, because the solid slab resistance PRd (clause 6.6.3.1(1)) may be reduced using the factors kl (clause 6.6.4.1(2)) and kt (clause 6.6.4.2(1)) used to allow for the presence of decking. SCI’s advice in P380 was that LAW should be used when determining reduction factors, not least because although the code itself is not clear, the ICE Designers’ Guide to Eurocode 4 by Prof. Roger Johnson used the LAW in the examples.

In addition, BS EN 1994-1-1, clause 6.6.5.8(1) suggests that the minimum embedment length, i.e. length of stud extending above the top of the deckling, should be 2d (where d is the stud diameter). Although considering the LAW when verifying this would be consistent, it would also suggest that a nominal 100 mm stud of 19 mm diameter could not be used with 60 mm decking. Experience and tests have shown that such a conclusion would be incorrect. It is therefore reconfirmed that, although apparently inconsistent, the nominal stud length may be used when establishing this lower bound length.

Results of test programme and analysis

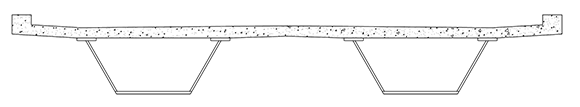

As well as considering what values to use for the variables in code rules, the test programme referred to was undertaken to confirm what resistances and slip capacities, can be achieved when studs are used with modern forms of profiled decking. The tests also investigated the justification for the detailing requirement given in BS EN 1994-1-1 that any mesh local to the studs should be placed at least 30 mm below the head of the studs. Note that this criterion is not satisfied with the very common situation in the UK of a 60 mm trapezoidal deck used with nominal 100 mm studs.

The conclusions from this test programme are provided in reference 1, and guidance given therein confirms the recommendation that the as-welded height (LAW) is used in the BS EN 1994-1-1 reduction formulae.

More significantly, the results also show that when the decking is transverse to the beam the rules given in BS EN 1994-1-1 may be unconservative. To allow for this, additional reduction factors to those given in BS EN 1994-1-1 associated with the decking geometry are required as described:

- when double studs are present additional reduction factors are introduced as follows:

- When mesh is placed below the heads of the studs an additional multiplication factor kmod of 0.9 should be applied. The mesh does not need to be 30 mm below the head, merely underneath it.

- When mesh is placed at nominal cover (assumed to mean above the head given typical slab geometries) the values derived from EN 1994 should be reduced using an additional multiplication factor kmod of 0.7. For studs with transverse decking:

PRd = kmodktMIN[PRdsolid slab]

- no further reduction is necessary when single studs are used, even if mesh is placed at nominal cover.

In addition, much research has been carried out in continental Europe as part of the background to new rules that will be presented in the so-called Generation 2 EN 1994-1-1. These suggest that some current UK practice may be unconservative, although this may simply be because of conservatism of the mechanical models that have been developed to predict resistance. The Generation 2 document will also allow the use of test derived values.

One final point for designers to be aware of is that studs come in standard lengths (of which 100 and 125 mm are the most common). A designer may consider increasing the length of a stud to (potentially) increase resistance, but only standard lengths should be specified.

Contact: Advisory Desk

Tel: 01344 636555

Email: advisory@steel-sci.com

References

2 BS EN 1994-1-1:2004 Eurocode 4 Design of composite steel and concrete structures. General rules and rules for buildings (incorporating corrigendum April 2009)