50 & 20 Years Ago

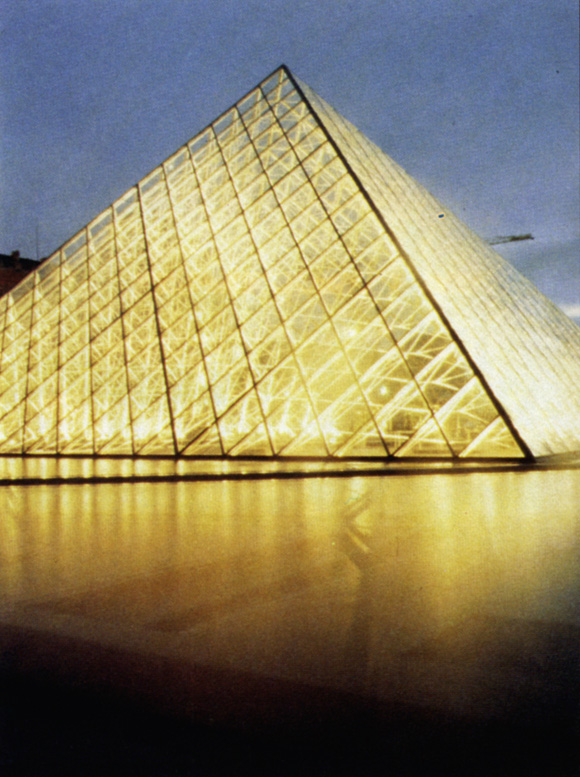

20 Years Ago: La Pyramide du Louvre – 1989 ECCS design award winner

In the heart of the Napoleon courtyard which marks the historical centre of Paris, the Louvre Pyramid is a steel masterpiece which opens the way to the new entrance to the Louvre Museum. It is the keystone of the Grande Louvre Project. This superb construction will enable the 4.5 million yearly visitors entering the new entrance hall to benefit from a sky lit route to their directions, thanks to the built in transparency. The pure lines of the pyramid, timelessly modern, are a symbol of the revival to this great museum.

Each side of the pyramid consists of a system of diamond-shaped cones produced by 128 intercrossing lattice girders of 16 different lengths. The outer faces of the girders consist of stainless steel bars welded to cast nodes. 16 rows of guy wires hoop the system to provide structural integrity under the strains resulting from wind, temperature variations and the concrete support.

CFEM, a subsidiary of USINOR SACILOR, which also incorporates the company GUSTAVE EIFFEL had to cope with a computing and development challenge involving the production of the finest possible structure within the boundaries of the geometry specified by the architect.

The cast nodes were produced by the lost wax process. The ancient technique put to use with stainless steel enabled the achievement of a high quality surface finish.

The guys providing the structural tension are comparable to those of large modern sail boats and develop exceptional technical features. The outstanding features of the Pyramid are:

• its lightness and the transparency resulting from the slenderness of every component, from the high standard of the glazing laid and from the absolute flatness of the sides

• exceptionally close building tolerances (<1mm)

• structural complexity resulting from the number of nodes and modelized bars.

The concurrent execution of both concrete structures and erection required use of a structural bearing scaffolding. Leg jacks were used to make up for the prestressing fluctuations of the bearing girders. Close geometrical testing took place after each erection weld. Ballasts simulating the weight of each glazed panel were carried out to correct the flatness of the sides before the panels were put in place. The length of the guys was adjusted as required by the actual 3D location of each node.

The Pyramid was completed within 30 months including eight for design, eight for fabrication and 14 for erection (January 1986 – June 1988).

Judges’ Comments:

An outstanding solution to a unique project incorporating many important technical details enabling the minimum amount of steel to be visible.

Owner: Public du Grand Louvre

Architects: Ieoh Ming Pei

Structural Engineers: Ieoh Ming Pei & Partner Steelwork Contractor: CFEM