Technical

The real vibration performance of modern steel-framed floors

The use of steel-concrete composite floor systems for multi-storey construction has increased dramatically over recent years. Dr Stephen Hicks, Building Engineering Manager at the Steel Construction Institute, analyses the vibration performance issues.

The recent increase in the use of steel-concrete composite floors is largely due to the response of the construction industry to clients’ demands for buildings that are fast to construct, have large uninterrupted floor areas and are capable of accommodating a high degree of servicing. However, as a consequence of these developments, serviceability issues relating to the vibration response of the floor are sometimes becoming the governing design criteria because long slender spans can be readily achieved; the natural frequencies can be low; the construction is relatively light in weight; and the level of damping can be low. The recent highly publicised vibration serviceability problem with the Millennium Bridge in London has focused designers’ attention on issues related to human acceptance of vibration.

Human perception of vibration

There are many possible ways in which the magnitude of the vibration response can be measured. However, due to the fact that instrumentation for measuring acceleration is normally more convenient, many modern standards describe the severity of human exposure to vibration in terms of acceleration.

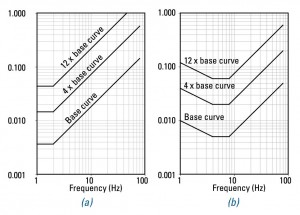

Figure 2: BS 6472: 1992, ISO 2631-2: 1982 and ANSI S3.29: 1983 building vibration curves for (a) x- and y-axis vibrations and (b) z-axis vibrations

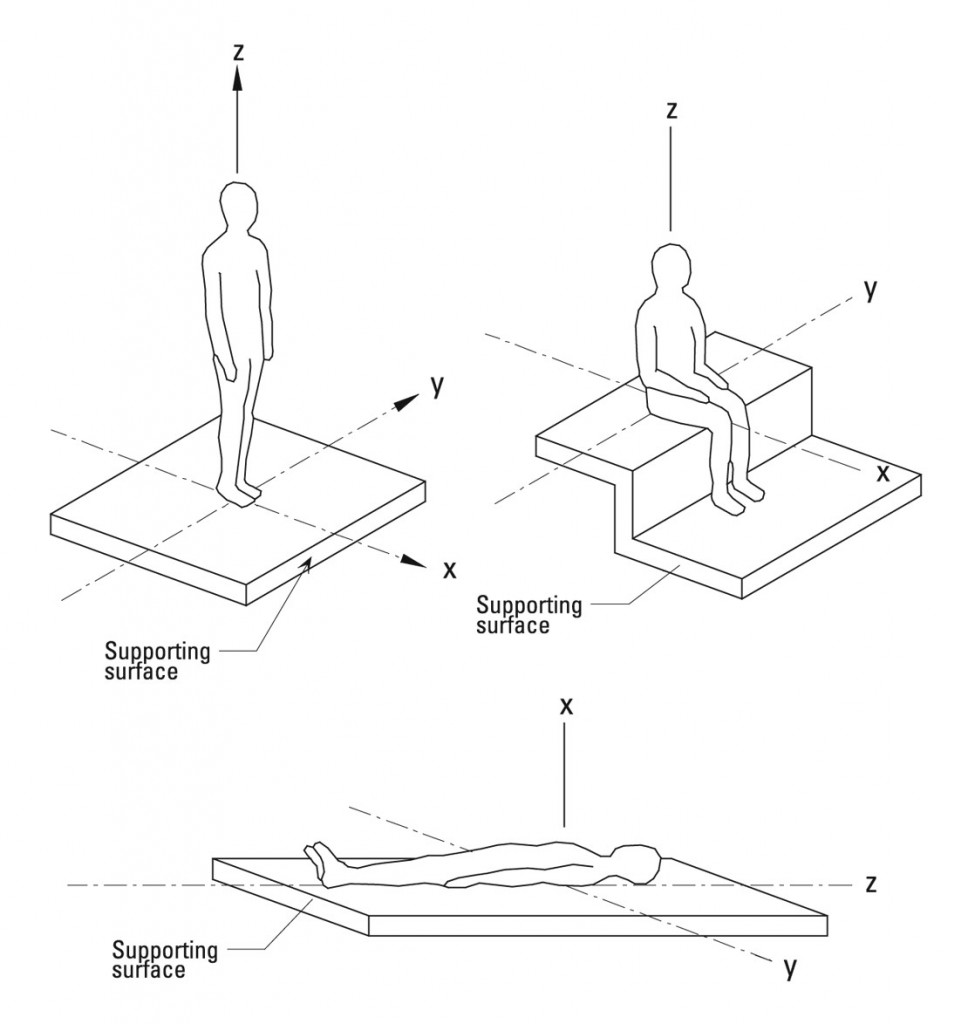

The perception of vibrations depends on the direction of incidence to the human body. To account for this, most modern standards use the ‘basicentric’ coordinate system shown in Figure 1 in which the z-axis corresponds to the direction of the human spine.

The standards BS 6472: 1992, ISO 2631-2: 1982 and ANSI S3.29 1983 are probably the most widely used codes of practice in modern design. These standards provide curves (known as ‘base curves’) that represent the variation of human perception with frequency for vibrations in x-, y- and z-axis. These base curves are plotted on graphs of root-mean-square (RMS) acceleration against frequency (see Figure 2).

To enable these standards to cover many vibration environments in buildings, limits of satisfactory vibration magnitude are expressed in relation to the base curve by a series of multiplying factors that are applied to the RMS acceleration (also known as ‘response factors’). The base curve for vibrations in the x-, y- and z-axis, together with a range of typical factored curves, is shown in Figure 2. Each line in Figure 2 represents a constant level of human reaction known as an isoperceptibility line: the area above a line corresponds to an unacceptable human reaction.

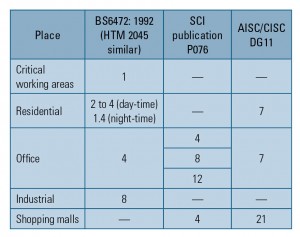

BS6472: 1992 recommends that the response factors given in the second column of Table 1 should be applied to the base curve to provide a ‘low probability of adverse comment’ when continuous vibrations are considered. The NHS performance standard, Health Technical Memorandum 2045 (HTM2045), suggests that reponse factors for critical working areas, residential, office and industrial environments are appropriate for operating theatres, wards, general laboratories and workshops respectively.

From experience of vibrations on particular floor types, additional reponse factors are recommended by SCI publication 076 and American Institute of Steel Construction/Canadian Institute of Steel Construction Design Guide 11; these are given in the third and fourth column of Table 1 for comparison purposes.

Although the British Standards and Eurocodes require the designer to consider the effect of vibrations, they normally suggest that specialist literature should be considered for advice on the topic. For normal steel-framed floors, design guidance for vibration is provided in SCI publication 076, together with a series of accompanying Advisory Desk notes (AD253, AD254 and AD256). To supplement this guidance, SCI publication 331 has recently been produced for sensitive floors, such as those encountered in operating theatres within hospitals. For the special case of dance-floors, where the synchronised activities from crowds produce loads that should be considered at the ultimate limit state, BRE Digest 426 should be consulted.

Vibration tests on steel-concrete composite floors

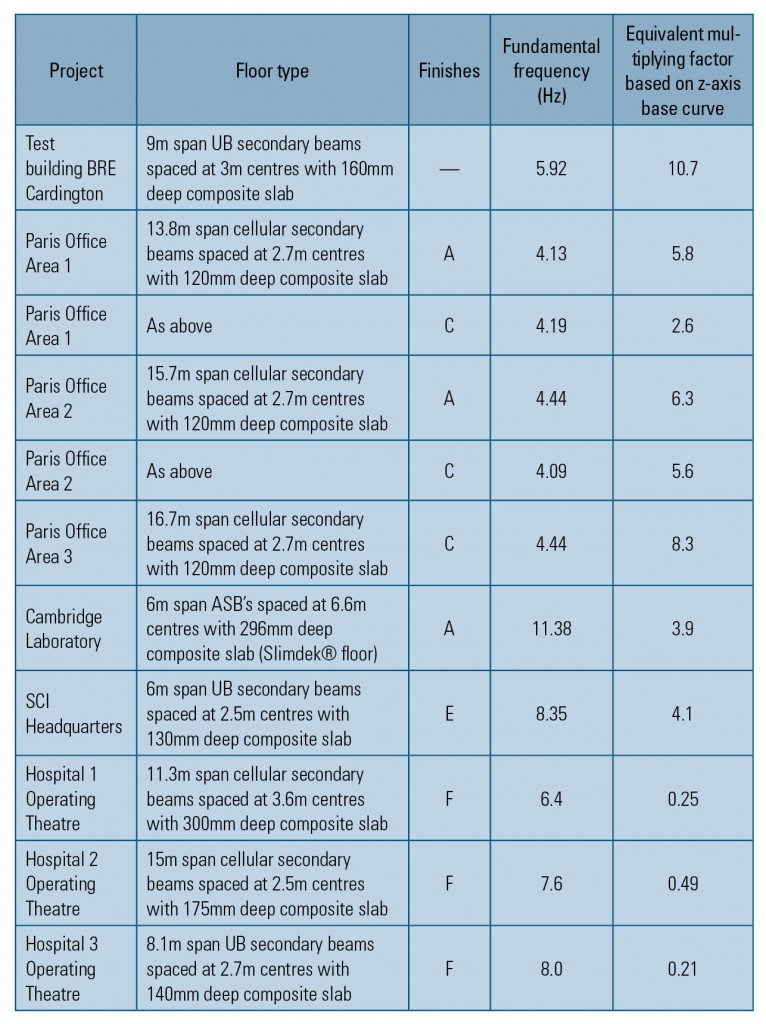

Over the last seven years, vibration testing has been undertaken on a wide range of floor types. The reason for these tests has been to provide a better understanding of the vibration behaviour of steel-framed floors, and to demonstrate the conservatism that exists within the current design guides when compared to measurements from real floors. A selection of floors that have been subjected to vibration tests is shown in Table 2.

Table 2 – Measured dynamic properties of 11 composite floors (Notes: A = Services, C = False floor and services, E = False floor, Services, Furniture, Partitions, F = Floor finishes, Services, Partitions)

This table presents the measured fundamental (first mode) frequency and the corresponding worst-case response factor from walking activities carried out on the test floors. The wide scatter of the natural frequencies reflects the range of structural types tested.

As can be seen from the table, all the floors tested easily satisfied the appropriate performance standards shown in Table 1 for office, laboratory and operating theatre environments (using the SCI parameters for the offices). In particular, for the three hospital floors that had operating theatre areas, it can be seen that the response factors were two to four times better than the HTM 2045 requirements.

Since acceleration response is inversely proportional to mass, it would indicate that significant reductions to the slab thicknesses could have been made in these cases. The above table also shows the effect of increased levels of damping when different non-structural finishes are applied to the floor. For example, the highest response factor measured was for a floor where no finishes were present (the BRE test building, Cardington).

As reported in the November/December 2004 issue of New Steel Construction, through extensive back-analysis of measurements on real floors using finite element models the SCI has developed analysis software that is capable of providing much more accurate predictions of the floor response when subject to walking. The engineers of the Slimdek floor to the Diagnosis & Treatment Centre at St Richard’s Hospital, Chichester have taken full advantage of this capability, which led to a 40% reduction in steel weight. As well as being applicable to other forms of structures, the analysis software has also been extended to predict the dynamic performance due to different loading types such as aerobic and crowd loads.

To date, the SCI has worked closely with a number of engineers to optimise their structures for vibrations at pre-construction stage and, on the rare occasion when floors have been found to be problematic in service, assessments have also been made on the completed structures. These structures have consisted of office floors, operating theatres, structures subjected to synchronized crowd loads and staircases.