50 & 20 Years Ago

40 Years Ago: GEAI, Rouen

Taken from Building with Steel, 1969

France has sought to solve its desperate housing problems by making use of prefabricated structures. For this purpose, various consortia have been established; one of these, formed in 1962 and consisting of architects and industrialists is known as GEAI (Groupement pour l’Etude d’une Architecture Industrialisée). As a result of their investigations, GEAI were able to construct a prototype block of flats in Auberviliers early in 1966, the principle virtue of which was that a completely dry system of construction was involved above the foundations. Subsequently, a scheme for 25 blocks of 20 dwellings was prepared for a site in Rouen, the scheme being known as ‘Grand’Mare III’.

Structural elements

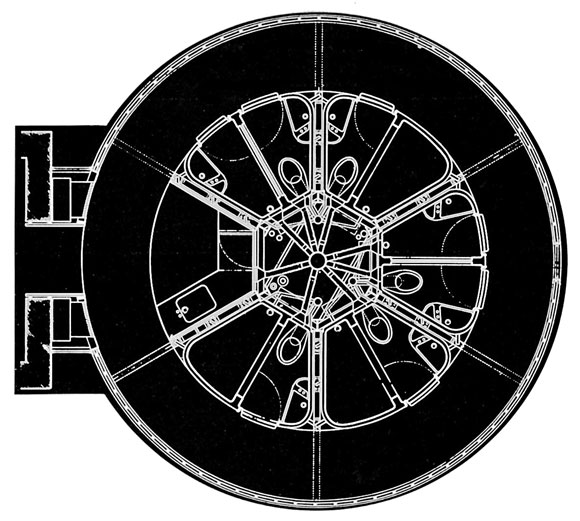

The elements erected on the site are relatively few in number. The loads are carried by steel columns and an unusual floor and roofing system comprising components reminiscent of mattresses. These consist of three-dimensional latticed frames 300mm deep, formed into panels based on a 900mm square module, typical sizes on plan being 3.6m × 2.7m, 4.5m × 2.7m and 5.4m × 2.7m. Within the blocks are steel staircases, but provision could be made for lifts.

The floors consist of thin concrete slabs and the ceilings, interlocked chipboard panels. Dry partitions, either permanent or temporary, are used, together with prefabricated wall panels, balcony balustrading, joinery and blinds. All the main elements have been subjected to fire tests, with completely satisfactory results.

The most original item in the GEAI system in undoubtedly the floor mattress. The standard panels comprise top and bottom grids, made from 10mm round bars at 300mm centres in both directions. These grids are staggered by 150mm in both directions with respect to one another in order to accommodate the 8m lacing bars providing the infilling. The main framework around the mattress consists of four lattice girders comprising angle chords and flat web members. All the units are interchangeable as they are specially fabricated in jigs. There are also special panels to allow for the passage of vertical ducts, etc.

A particular feature in the Grand’Mare III scheme is that the exposed steelwork is in Cor-ten weathering steel. To prevent any possible staining in the early stages of oxidation, the columns are offset from the facades by the insertion of special brackets.

Construction

This scheme occupies two adjacent sites where provision has been made for 100 three room flats, 312 four room flats and 88 five room flats.

The twenty five blocks are all five storeys high, the ground floor of each limited to the entrance hall, a perambulator area, a dustbin store and the central heating unit.

Despite the fact that the weight of the GEAI structures is about one quarter that of traditional buildings of the same volume and use, it was necessary to employ some piled foundations as the sub-soil conditions were not good. There were eight driven piles per block, 35 concrete bases and a lean-mix slab for the enclosed portions of the ground floor.

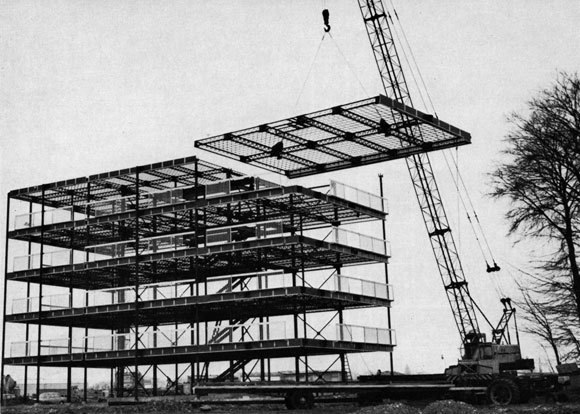

Apart from the pile-driving equipment, the only vehicles on the site were lorries which delivered the components and mobile cranes which erected them.

Once the foundations and bases for a block of flats had been completed it was possible to start erection. To ensure stability, braced panels are incorporated in the design as strong points. These units, consisting of two 180mm deep column sections, 15m high and spaced at 3.6m centres, braced with channels and angles and completely fabricated in the shops, were the first components to be erected on the site where they were held in position by temporary guys until sufficient steelwork had been erected to make the structure stable in all directions.

The central parts of the blocks are reserved for central circulation and for the landings serving the flats. The landings and the corresponding portions of the roof were made from 5mm thick plate and light joists.

This steelwork, which was shot blasted and painted, together with the staircase steel, was the only steelwork not in Cor-ten.

On the site the various mattresses were bolted edge to edge to make up very large floor units which were then hoisted by mobile crane. Once the steelwork had been erected it was possible to fix the partitions and cladding extremely quickly. In fact the whole operation could proceed almost independently of the weather.