Projects and Features

Weathering Steel Bridges

Corus anticipates a dramatic increase in the use of weathering steel in bridges following the recent publication of design standard BD7/01 Weathering Steel for Highway Structures. There is now a growing appreciation of the behaviour of weathering steel and the key benefits it can bring to a project. These include lower capital cost and very low maintenance.

The minimal future maintenance requirement greatly reduces the whole life cost, and yields both environmental and health and safety benefits. There is also a greater interest in, and acceptance of, the natural appearance of mature weathering steel bridges, which often blend pleasingly with the environment.

Major Changes in BD7/01

BD7/01 incorporates the outcome of recent research into the corrosivity of the environment under bridge decks, and the inservice performance of weathering steel used in bridges. It also draws on the experiences of other countries with weathering steel highway bridges. The key changes in the new version are as follows:

- The 7.5m minimum headroom limitation for bridges over roads subjected to de-icing salt has been removed, so weathering steel bridges are now permitted to be designed at standard headrooms.

- Corrosion allowances have been reduced.

- A minimum headroom for bridges over water of 2.5m has been introduced. • Guidance on the design and detailing of such bridges has been expanded.

- Additional information on inspection, monitoring and maintenance has been included.

Corus Developments

In the light of the changes to BD7/01, Corus has been considering the whole steelwork package to improve the competitiveness of weathering steel bridges and promote their use. Corus has developed a new low CEV weathering steel for improved weldability, and addressed the key issue of availability. It has clarified the availability of weathering steel plate and sections, developed a limited range of weathering steel angles and channels which are available in small quantities from Armstrong Glen Metals, and has worked with Cooper and Turner on the availability of weathering grade HSFG bolts in metric sizes.

Availability

Plates

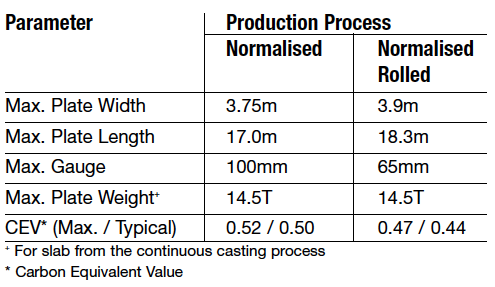

Plates may be obtained direct from the mill, where a minimum quantity of five tonnes per width and thickness applies, or from Armstrong Glen Metals (the main steel stockist for weathering grades). Corus currently supplies S355J0W, S355J2W and S355K2W weathering steel grades to BS EN 10155 within the following parameters.

Sections

Sections

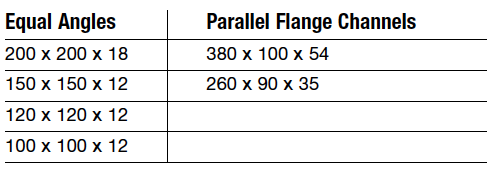

The minimum quantity for sections (UBs, UCs, channels and angles etc.) direct from the mill is 50 tonnes per size and weight. Smaller quantities may be available depending on the availability of suitable feedstock and gaps in the rolling programme, but this cannot be relied upon at the design stage. However, Corus, in association with Armstrong Glen Metals, has created a stock of a limited range of angles and channels to support the weathering steel bridge market. Hence, for these sections, small orders for angles and channels used for bracing elements can be fulfilled. Details of the sections stocked are as follows:

Hollow Sections

Hollow Sections

The minimum quantity for hollow sections specified to BS 7668: 1994 is 150 tonnes per order, as a cast will have to be made specially. Within this quantity, a mixture of section sizes may be ordered, with the minimum quantity of each section being dependent on the section size.

HSFG Bolts

Over recent years, weather resistant grade HSFG bolts have been imported from North America in imperial sizes. However, Cooper and Turner in the UK now stocks weather resistant grade HSFG bolts, with chemical compositions complying with ASTM, A325, Type 3, Grade A, in metric sizes (M20, M24 & M30).

New Weathering Steel Bridges Brochure

New Weathering Steel Bridges Brochure

Corus has produced a new publication, entitled Weathering Steel Bridges, which draws together the revisions to BD7, the material availability information and the benefits and limitations. It outlines the behaviour of the material, provides guidance on a range of issues including; design, detailing, fabrication, inspection, monitoring, and maintenance, and is illustrated throughout with photos of mature weathering steel bridges.

The brochure may be obtained through the Corus literature ‘hotline’ – Tel: 01724 404400.

Chris Dolling, Bridge Market Development Manager, Corus Construction Centre.