Projects and Features

New SCI publication on steel castings

Modern steel construction continually pushes boundaries, demanding greater complexity and enhanced aesthetic appeal, while maintaining, or even increasing, material efficiency. As architects and engineers envision more ambitious structures, the limitations of traditional fabrication methods can sometimes present challenges at the joints between members. Structural steel castings offer a viable alternative to conventional fabrication for such connections and components, but they remain an often under-utilised solution. The Steel Construction Institute’s (SCI) new Publication P441, Structural Steel Castings, provides a comprehensive technical resource for engineers, designers, and fabricators. This publication represents a significant update to the earlier SCI guide P172 Castings in Construction, reflecting almost three decades of advances in analysis, manufacturing, and application. Max Cooper of the SCI offers an overview of key guidance within P441, examining the engineering advantages, practical applications, procurement considerations, and quality management associated with structural steel castings.

Engineering Advantages of Structural Steel Castings

SCI Publication P441 extensively details the engineering merits of employing steel castings, which can yield significant benefits in terms of structural performance, design optimisation, and construction efficiency.

Optimised Geometries and Material Utilisation

The casting process allows the creation of components with highly complex, three-dimensional geometries that are challenging or unachievable through standard fabrication techniques. This allows for the optimal shaping of connections to align with stress paths, for instance, by gradually tapering wall thicknesses to meet varying load demands or transitioning cross-sectional shapes to match the incoming members. Such optimisation can minimise stress concentrations and improve fatigue performance. Material can be distributed precisely where structurally required, enabling efficient load transfer and potentially reducing overall component weight compared to fabricated alternatives built up from standard sections and plates. This is particularly evident where multiple members with different profiles or orientations converge at a single point.

Enhanced Structural Characteristics

Cast steel components typically exhibit isotropic material properties, providing uniform strength and ductility in all directions. This is particularly advantageous for connections subjected to multi-axial stress states where the directional properties of wrought materials might be a limiting factor. The monolithic nature of castings eliminates bolted or welded joints within the component itself, which can be sources of stress concentration or points of initiation for fatigue cracking. Well-designed castings, often benefiting from smooth fillets and gradual changes in section, can offer superior fatigue resistance compared to equivalent fabricated connections, leading to extended service life for the structure.

Fabrication Simplification and Construction Precision

The use of castings can simplify the fabrication of complex nodes by reducing the number of individual pieces and the extent of complex welding. Welds are typically relocated from highly stressed zones within the node to simpler, more accessible interfaces between the casting and adjoining steel members. This not only improves weld quality but can also reduce inspection burdens. Dimensional accuracy of critical interfaces, such as mating surfaces or bolt hole locations, can be achieved through post-cast machining, often utilising CNC processes to tight tolerances. This precision leads to improved fit-up on site, reduced erection times, and lower risks of costly rework. Features such as integrated lifting lugs, temporary erection supports, or specific weld preparations can also be incorporated directly into the casting design, further streamlining site operations.

Understanding Steel Castings: The Process and Product

At its core, a steel casting is a component formed to a near-net shape by pouring molten steel into a mould containing a cavity of the desired geometry. Once the metal cools and solidifies, the mould is removed, and the casting undergoes various finishing processes. While different casting methods exist, sand casting is the most common for structural steel applications.

The typical sand-casting process involves several key stages:

- Pattern Making: A pattern, which is a replica of the final part (oversized to account for metal shrinkage during cooling), is created. Patterns can be made from materials like wood, plastic, or metal and are commonly CNC machined.

- Mould Creation: The pattern is used to create a cavity in a refractory moulding material, which is typically sand mixed with a bonding agent. For complex internal geometries, cores (also usually made of sand) are placed within the mould. The mould is often made in two or more parts to allow for pattern removal and subsequent assembly.

- Melting and Pouring: Steel scrap, with precise additions of virgin alloys to achieve the desired grade, is melted in a furnace (commonly an Electric Arc Furnace) to temperatures around 1600°C. The molten steel is then poured into the assembled mould cavity through a carefully designed gating system, which controls the flow of the molten steel and helps prevent defects.

- Solidification and Cooling: The molten steel solidifies within the mould, taking the shape of the cavity. The rate of cooling is a critical factor influencing the final microstructure and properties of the casting.

- Shakeout and Finishing (Fettling): Once cooled, the casting is removed from the mould (shakeout). Excess material, such as the gating system and any feeders (reservoirs of molten metal that compensate for shrinkage), is removed. The casting surface is cleaned, typically by shot blasting.

- Heat Treatment: Most structural castings undergo heat treatment processes (e.g., annealing, normalising, quenching and tempering) to refine the grain structure of the metal and achieve the specified mechanical properties, such as strength, toughness, and ductility.

- Inspection and Machining: The casting is then inspected using various non-destructive testing (NDT) methods. If required, critical surfaces or features like bolt holes are machined to achieve precise dimensional tolerances.

This process, though complex, allows for the creation of monolithic components with geometries that are often impractical or impossible to achieve through traditional fabrication from steel plates and sections.

Case Studies from SCI P441

The practical application and benefits of steel castings are illustrated in SCI P441 through several notable case studies, showcasing both bespoke and standardised solutions.

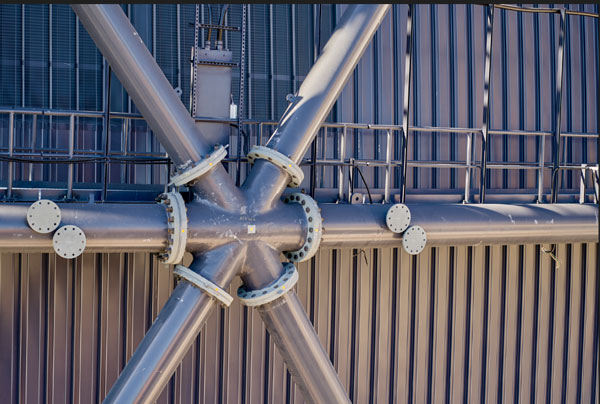

The MSG Sphere, Las Vegas

The construction of this large-diameter spherical structure required cast steel nodes to connect the circular hollow sections of its exosphere. The complex, multi-planar geometry of these connections, each typically joining six members, presented a significant fabrication challenge. The adoption of 368 bespoke cast steel nodes supplied by Cast Connex, with individual weights up to 6.5 tonnes, resulted in substantial advantages over fabricated alternatives. These included a reported 57% weight reduction, a 76% decrease in the number of bolts, and a 76% reduction in surface area requiring coating for a typical node. CNC machining of the casting flanges ensured the geometric accuracy required for assembly. The project also utilised standardised or “off-the-shelf” cast field-bolted splice components for circular hollow sections (also from Cast Connex), demonstrating the versatility of casting solutions.

Western Concourse, King’s Cross Station, London

For the roof structure of the Western Concourse, 1.5-tonne multi-planar cast steel nodes were employed to connect the tapering elliptical columns to the steel diagrid shell. The castings were instrumental in realising the complex, organic architectural forms while fulfilling the structural load transfer requirements. The alternative of fabricating these nodes would have involved extensive and highly complex welding operations, making the aesthetic and structural vision difficult to achieve with the same level of refinement.

the fabrication shop © John McAslan + Partners

Procurement and Design Considerations

SCI P441 provides detailed guidance on the procurement process and design considerations specific to custom steel castings, an area where early decisions significantly impact project outcomes.

Procurement Routes

The publication discusses two primary procurement models. For project teams with limited prior experience in castings, the engagement of a specialist ‘casting designer-supplier’ is recommended. Designer-suppliers, such as companies like Cast Connex, provide expertise from conceptual design assistance and detailed engineering through to foundry liaison, quality assurance, and supply. This integrated approach can reduce risk in the process for the main project team.

The alternative, traditional route involves direct engagement between the steelwork contractor and the foundry, necessitating a higher degree of specialist knowledge within the contractor and principal design team. Regardless of the chosen model, early engagement with casting specialists or foundries is emphasised to ensure technical feasibility, define clear performance requirements, and establish realistic programmes and cost estimates.

Design and Specification Process

The design of structural castings is an iterative process that must balance structural performance, architectural intent, and manufacturability (castability). SCI P441 highlights the use of Finite Element Analysis (FEA) for optimising casting geometry and verifying structural adequacy under design loads. This often involves multiple iterations to refine shapes, minimise weight, and ensure stress levels are within permissible limits. Early collaboration between the structural engineer, architect, steelwork contractor, and the casting specialist is crucial to harness the full potential of castings. The development of comprehensive documentation, including a Performance Requirements Report (defining loads, service conditions, and applicable standards) and a Casting Design Report (detailing the proposed geometry, material grade, and analysis results), is crucial. The product standard for structural castings in the UK is BS EN 10340 Steel Castings for Structural Uses, which covers a range of carbon and stainless steel grades and their associated mechanical properties.

Quality Management and Sustainability

Effective quality management is critical to the successful use of steel castings and is thoroughly addressed in the new guide. Sustainability is also an important consideration in the use of steel castings.

Quality Assurance and NDT

SCI P441 underscores the importance of robust quality control measures throughout the casting production process. This includes foundry accreditations (e.g., BS EN 10340 and ISO 9001 quality management systems) and a well-defined inspection and testing plan, agreed between the specifier and the foundry. The publication details various non-destructive testing (NDT) techniques applicable to castings, such as visual testing (VT), magnetic particle testing (MT), liquid penetrant testing (PT), ultrasonic testing (UT), and radiographic testing (RT). Crucially, it advises on the specification of appropriate NDT methods and acceptance criteria (severity levels) related to the service conditions and criticality of the specific casting, cautioning against overly stringent, blanket requirements that may lead to unnecessary cost. A well-defined NDT programme, tailored to the casting’s function, provides vital confidence to all project stakeholders.

Sustainability Considerations

Steel castings offer several sustainability advantages. The casting process allows for ‘near-net shape’ manufacturing, optimising material utilisation and minimising the generation of waste material compared to subtractive manufacturing processes. The reduction in welding achieved by using monolithic cast nodes can also lead to a decrease in welding consumables and associated energy consumption. Furthermore, the potential for enhanced durability and fatigue life in cast components can contribute to extended structural service lives and reduced whole-life carbon impacts. The optimised, often lighter, cast components can also lead to secondary benefits such as reduced transportation emissions and reduced demands on supporting structures and foundations. The smoother profiles of castings can also improve the longevity of protective coating systems, reducing maintenance interventions.

The role of SCI P441

Structural steel castings provide a valuable engineering solution for complex structural components and connections, offering benefits in design flexibility, structural efficiency, and construction. The effective specification, design, and procurement of these components requires specialist knowledge. SCI Publication P441, developed with support from industry leaders Cast Connex, serves as a significant technical reference for the constructional steelwork industry. It equips professionals with all the necessary information to assess the suitability of castings and to implement them successfully in projects.

SCI P441: Structural Steel Castings is available as a free PDF download for all SCI members through SteelBiz, and can be found at www.steel-sci.com.