Technical

AD 276: The Use of ‘Toggle Bolts’

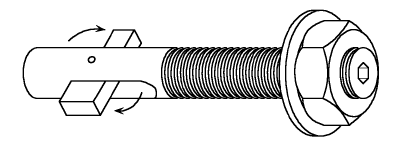

It has come to our attention that increasing use is being made of ‘toggle bolts’ for blind fixing to hollow sections. A ‘toggle bolt’ (fig. 1) has a pivoted bar which lies within the bolt shank as it is inserted through a hole drilled in the section. Once the pivoted bar is through the section wall, the pivot bar turns through 90º under gravity and prevents the bolt being pulled back out of the hole.

Some caution is required when using these bolts for the following reasons:

Shear Resistance

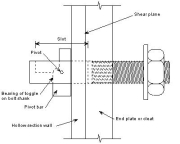

Quoted shear resistance is often that appropriate to the threaded shank. However, given the small wall thickness of most hollow sections, the shear plane will almost always fall in the slotted zone of the bolt (fig. 2), where the resistance will be much reduced.

Bearing Resistance

One of the bearing interfaces will undoubtedly be the slotted portion of the bolt against the hollow section wall. It is not clear how the bearing resistance should be calculated, as the contact is not between a solid circular bolt in a circular hole. Furthermore, unlike the plies between a normal bolt head and nut, the material is not constrained all around the hole, but only locally by the toggle.

Shear and Tension Resistance

The behaviour of a ‘toggle bolt’ is obviously complex since the reaction against a tension force is not concentric to the bolt shank – the toggle only bears on one half of the bolt shank. The pivot does not transfer axial load. Tension will therefore induce some degree of bending, which must be carried across the slotted length of the bolt in combination with applied shear.

Detailing Requirements

Care should be taken with detailing dimensions in hollow sections in order to ensure that the pivoted bar can fully rotate when the ‘toggle bolt’ has been inserted. Designers are reminded that the rules in BS 5950-1 are based on standard circular bolts, and it is doubtful if the strengths and design rules in the Standard can be directly applied to non-standard bolts. Designers using ‘toggle bolts’ should reassure themselves that the values quoted by manufacturers are appropriate for the application envisaged.