Projects and Features

School design is future-proofed

Two schools creating an education campus for a new Cambridgeshire community have maximised the benefits that steel construction can offer.

FACT FILE

Alconbury Weald Church Academy, Cambridgeshire

Main client: Cambridgeshire County Council

Architect: R H Partnership Architects

Main contractor: Morgan Sindall Construction

Structural engineer: Sweco

Steelwork contractor: AC Bacon Engineering

Steel tonnage: 450t

With plans for the construction of more than 6,000 homes, a new community is taking off from the site of RAF Alconbury in Cambridgeshire.

Known as Alconbury Weald, the new town is being developed by Urban&Civic, who purchased the former MOD land, including the runway, in 2009. Outside of the development, a parcel of land remains as the military base, used by the US Air Force for non-flying operations.

As well as housing, Alconbury Weald will also have schools, industrial and office spaces, community and leisure facilities, shops and a health centre. Included within the infrastructure being built to serve the scheme, there is also a reserved plot for a possible railway station.

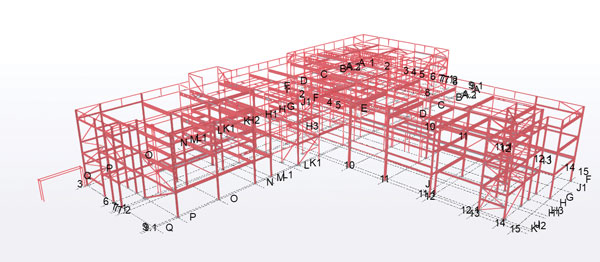

Set in the heart of the growing development and complementing the current primary school provision, two steel-framed schools will form the education campus: Prestley Wood Academy SEND School and Alconbury Weald Church Academy Secondary School.

The SEND school was completed in 2024 by Morgan Sindall Construction (with AC Bacon Engineering fabricating and erecting the steelwork) and now the two companies are working together again on the secondary school.

Cambridgeshire County Council is delivering the school in line with its aspirations for sustainability, energy efficiency and best practice design in order to reduce the inherent energy demand and associated CO₂ emissions of the building.

In response to this, the school incorporates effective passive design measures through the adoption of a fabric-first approach, followed by the use of low-carbon energy sources in the form of air source heat pumps. Energy demand is then further reduced using zero carbon energy generators in the form of solar photovoltaic (PV) panels located at roof level.

The efficient design includes a steel frame that supports precast flooring planks, a solution chosen for its speed, structural and thermal mass qualities and associated lower emissions, according to Morgan Sindall Senior Project Manager Gareth Harris.

“The underside of the planks and M&E services will remain exposed in areas of the completed building, allowing the floors to absorb heat during the day and dissipate it at night, in line with the MEP design strategy for the scheme.”

Consisting of a three-storey teaching block and a separate sports hall, Alconbury Weald Church Academy will initially cater for 600 pupils as a 4 Form of Entry (4FE) secondary school. However, there is flexibility with the project’s design to facilitate a potential future expansion to an 8FE/1,200 pupil school, when required.

The building is T-shaped on plan, with the horizontal wing accommodating a triple-height dining hall and a kitchen. The future expansion of the school would see this wing extended to provide additional accommodation.

To facilitate the extension, there is no bracing positioned in this gable end, meaning once the cladding had been removed, a new steel frame would be connected to the existing columns.

Aside from its flexibility, another benefit of using the steel-framed option has been its speed of construction. The 450t of steelwork that forms the main block and sports hall were erected in a seven-week programme.

Given the site is a former airfield, with few trees and little shelter, the construction is open to the elements and in particular the wind.

“We had a few periods when our lifting operations had to stop, due to wind, but otherwise we’ve had no challenges with the erection. We had the site pretty much to ourselves, which gave us plenty of space for materials to be stored,” says AC Bacon Engineering Project Manager Martin Whitehead.

Prior to the steelwork erection starting, the school’s brownfield plot underwent a remediation programme, followed by the installation of vibro-stone columns and pad foundations for the main block and sports hall.

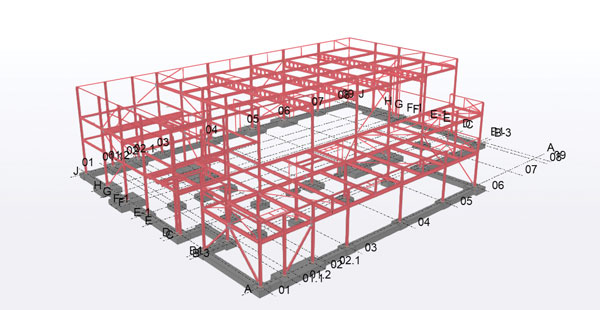

Using its own mobile cranes, AC Bacon erected the steel frame of the main block in four phases. Once each phase was complete, the area was handed over to the concrete contractor, who installed the precast planks, stairs and lift shaft.

“As well as its thermal mass attributes, the precast flooring solution was also used as it efficiently formed the required spans and allowed the classrooms and other facilities to be column-free,” says Sweco Senior Engineer Filipe Henriques.

Much of the main block features columns spaced at 7.2m centres, with internal members positioned within a central corridor that separates the building’s two rows of classrooms.

The exception to this column spacing is the aforementioned dining hall that has 9m-long spans and a double-height main hall/drama studio, which is formed with a series of 15m-long Westok beams.

The main block’s frame derives its stability from bracing, which is predominantly located around the stairwells and the lift shaft. With no cross-bracing within internal walls, further flexibility has been designed into the steel frame, whereby classrooms could be enlarged, if required, with the removal of partitions.

The adjacent sports hall adopts a similar design approach, with cross bracing located around the perimeter walls to provide stability. This structure has two parts: a double-height four-court sports hall, formed with a series of 20m-long Westok beams and a lower section that wraps around two elevations.

The lower part of the building will accommodate changing rooms, a multi-use activity studio and plant spaces. Both the sports hall and main block have areas of roof formed with metal decking, which was installed as part of AC Bacon’s package.

Summing up, Councillor Bryony Goodliffe, Chair of the Children and Young People Committee at Cambridgeshire County Council, says: “The Alconbury Weald Education Campus is an important investment for the County Council, supported by funding from Urban&Civic, and the new secondary school is central to that.

“We want to ensure all children and young people in Cambridgeshire have opportunities to thrive. I’m delighted that the Academy is set to provide those opportunities to the current and future residents of the new community.”

Alconbury Weald Church Academy is due to open in September 2027.

Mind the wind

The Alconbury Weald Church Academy project references the challenges of erecting steelwork in windy conditions. Max Cooper of the SCI offers some thoughts on what the structural engineer may need to consider on this topic, and where guidance can be found.

While the steelwork contractor generally manages site safety and develops the detailed erection method, the design engineer plays an important role in ensuring the stability of the part-erected structure. BCSA Publication 35/09 Guide to Steel Erection in Windy Conditions provides an excellent resource for the designer unsure of where their responsibilities begin and end.

As a general rule, the designer should have considered at least one way for the structure to be erected and must communicate their assumptions to the steelwork contractor. If specific temporary supports or reduced wind speeds are assumed in the design, these must be stated clearly in the design erection sequence.

Wind speeds during erection may safely be assumed to be lower than the wind speeds used to design the structure in the permanent condition. However, the manner in which stability is maintained in the temporary condition may differ significantly from that of the permanent condition, which therefore requires separate justification. The BCSA guide distinguishes between two temporary conditions which may be considered: transient and working.

For transient conditions (such as a partly erected frame left overnight), reduced design wind speeds may be calculated using the return periods in Table 3.1 of BS EN 1991-1-6. Users may be surprised at how small the reduction is for short-term temporary conditions (up to 3 days), where the return period should not be less than two years. Daytime “working” wind speeds may be assumed to be much lower, but require site personnel to be actively monitoring the weather and to be able to cease operations if conditions deteriorate.

During erection, column base connections of unbraced columns will be required to resist a base moment due to wind actions. More often than not, the column base has not yet been grouted and therefore normal moment-resisting base design procedures do not apply. In this state, the moment resistance of the connection relies on holding-down bolts acting in combination with steel packs or wedges. An upcoming joint SCI/BCSA publication on the design of column bases will explicitly cover this temporary design condition and include a worked example of such a case.

Designers must pay particular attention to tall, slender columns which are defined in the BCSA guide as columns taller than 10m with a height to width ratio exceeding 50. Tall, free-standing structures are susceptible to dynamic effects such as vortex shedding, which can occur at wind speeds well below the design limit. The designer should explicitly identify these conditions on the erection drawings and the overturning moments used for design should be increased by a dynamic factor of 1.20. Alternatively, the design erection sequence must stipulate that these columns are not to be left free-standing; they require immediate lateral support, such as guys or struts, before being released from the crane.