Projects and Features

Cornish waste and recycling solution

Structural steelwork has proven to be the ideal framing solution for the Hallenbeagle Waste Management Facility, one of the largest ongoing construction projects in the West Country.

FACT FILE

Hallenbeagle Waste Management Facility, Redruth

Main client: SUEZ Recycling and Recovery UK

Architect: Grainge Architects

Main contractor: Kier Construction

Structural engineer: Airey & Coles

Steelwork contractor: Billington Structures

Steel tonnage: 680t

Designed to increase Cornwall’s recycling rate and enhance the recently introduced household waste collection service, the steel-framed Hallenbeagle Waste Management Facility in Redruth is quickly taking shape.

Supporting Cornwall Council’s net zero carbon aspirations, the completed facility will be capable of processing up to 140,000t of locally sourced waste every year.

SUEZ Recycling and Recovery UK’s PFI General Manager for Cornwall and Devon, Mark Hillson, says: “The development of this facility will provide vital waste management and processing services for residents of Cornwall for generations to come.”

Councillor Loic Rich, Cabinet Member with responsibility for Environment and Climate Change at Cornwall Council, said: “Since introducing our new food waste, rubbish and recycling collections, our recycling rate has already increased to around 53%.

“The new waste management facility at Hallenbeagle will enable us to sort more recyclable materials before they are sent off for processing, in order to start a new lease of life.”

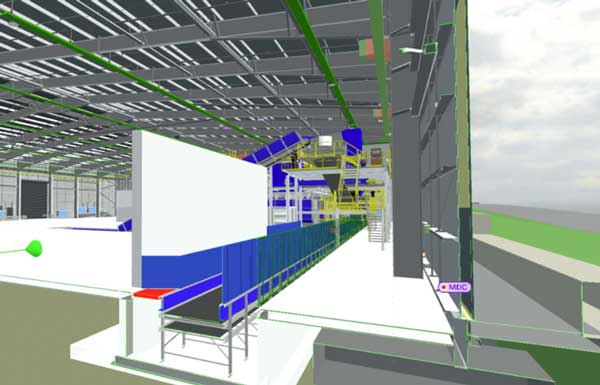

The overall scheme includes a single enclosed building that houses three separate zones: Refuse Transfer Station (RTS) where collection trucks will deliver waste; a materials recycling facility (MRF) where everything is sorted and processed; and the covered baler store where the paper, card, plastics and cans are baled.

The 8.264m² building measures 167m-long × 14m-high and consists of three separate, but interlinked steel portal frames (one for each zone) that have spans of 42m, 44m and 52m-wide respectively.

“The required speed of construction and the long clear internal spans, needed for the facility’s processing areas, meant structural steelwork was the only viable framing solution for this scheme,” explains Kier Construction Operations Manager Jeff Houghton.

As well as the main building, the 27,000m² site will also have covered storage for baled recyclable materials, an office block and parking for a fleet of waste collection trucks.

Located on a business park on the outskirts of the town, the site was once occupied by the Victorian-era Hallenbeagle copper mine. Due to its industrial past, the site initially underwent a remediation package, which lasted approximately eight months, before the build programme was able to kick-off.

Prior to the steelwork for the main processing building being erected, its concrete substructure and foundations were installed. The former consists of a series of push walls that surround the building and help subdivide it into the three zones.

The walls are up to 6m-tall in some areas and along the perimeter they are positioned inside the line of the steel frame’s columns.

Preventing any material from slipping between the walls and the structural frame, much of the building’s interior features a series of metal sheets, known as greedy boards. Requiring approximately 50t of steelwork, the boards are connected to the columns and overlap the perimeter concrete walls.

Meanwhile, supporting the steel columns, a series of large pad foundations, measuring up to 4m² and each requiring some 16m³ of concrete were also installed.

The perimeter columns are all full-height 14m-tall sections, while there are also two rows of internal columns, which are 8m-high and sat on top of concrete walls.

Structurally independent from the concrete substructure, the steelwork gains the majority of its stability from the portalisation of the three frames. However, because of the length of the structure, there are two rows of braced bays either side of the two internal divisions that provide additional rigidity.

For the erection process, steelwork contractor Billington Structures began with the installation of the covered baler store. This is the narrowest of the three portals and the area where the processed materials, having been sorted and compacted, are made ready for collection and delivery to the final destination (usually an energy-from-waste plant).

The second area to be erected was the 52m-wide MRF, the zone that will house Hallenbeagle’s processing equipment, followed by the RTS (where the collected waste arrives).

Spanning between the perimeter columns and creating the required open-plan areas, the roof structures for each of the three portals consist of a series of spliced rafters, brought to site in two pieces.

Using two mobile cranes, performing a dual lift, the sections for each span were individually lifted into place, with the central splice connection was made while they were still being held in position.

A lot of planning had to go into the positioning of the cranes, prior to the steel erection programme getting underway. A railway line runs along one of the site’s boundaries, and no material lifts could be undertaken near this important piece of infrastructure.

Billington Structures Project Manager Jodi Bath, says: “Being part of the Hallenbeagle project was an exciting opportunity.

“This facility is not just about waste disposal, but also about contributing to a sustainable future for Cornwall, which aligns with our own ESG objectives. We were proud to play a role in a development that will significantly improve recycling capacity in the region.”

Following on behind the steel erection team, the cladding contractor was already making the installed areas watertight, which in turn allowed the internal concrete floor slab to be cast.

Once all of these packages have been completed, the processing equipment will be installed inside the building as part of the final fit-out.

The Hallenbeagle Waste Management Facility is due to be operational in early 2026.