50 & 20 Years Ago

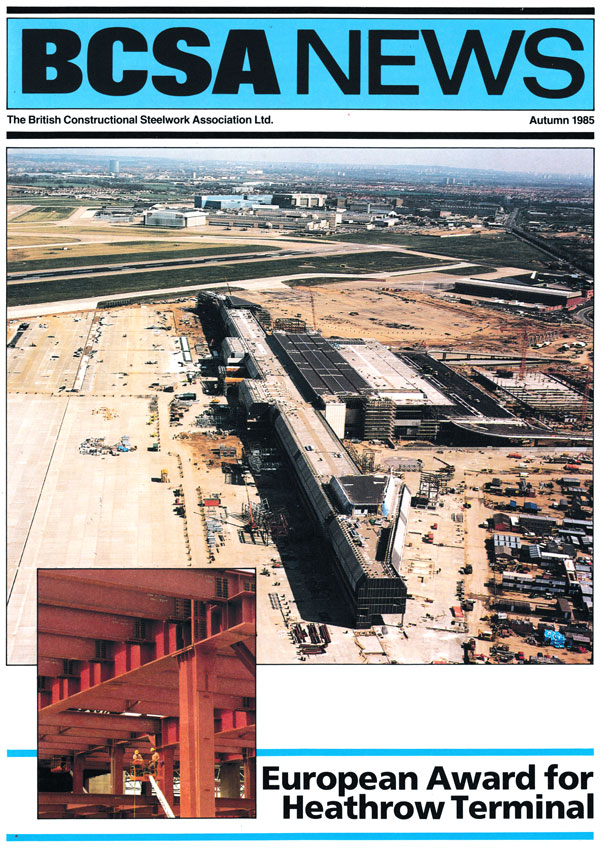

European Award for Terminal 4

From BCSA NEWS, Autumn 1985

THE 1985 European Design Award which is presented by the European Convention for Constructional Steelwork (ECCS) has been awarded to the new Terminal 4 Building at Heathrow Airport. The Award was presented at the 1985 Annual Meetings of the ECCS in Luxembourg on 12th September. Representatives from the Client (British Airports Authority), Management Contractor (Taylor Woodrow Construction), Consultant Architect (Scott Brownrigg & Turner), Consulting Structural and Civil Engineers (Scott Wilson Kirkpatrick & Partners) and the Steelwork Fabricators (Robert Watson & Co. Constructional Engineers Ltd.) were all present to receive the Award. BCSA Is the UK Member of the ECCS, which is the European platform for collaborative research and development In constructional steelwork.

British Airports Authority began the advance planning for Terminal 4 in the 1970’s to meet the demands of rapidly changing travel patterns and increasing size of aircraft predicted for the 1980’s.

British Airports Authority’s approach to the planning of T4 was to designate a site close to the southern perimeter road and the A.30 and to mount an architectural design competition. Four firms of architects were asked for design submissions in May 1977 with the winning solution having been submitted by Scott Brownrigg & Turner. Following the selection of the consultant architects, Scott Wilson Kirkpatrick and Partners were appointed structural and civil engineering consultants for the design of the terminal building, adjacent multi-story car park, access roads and flyovers.

The two firms had to work quickly to enable BAA to submit an outline planning application in September 1977. A public enquiry was held in 1978 and after a further year of government arbitration the go-ahead was finally given in late December 1979.

The British Airports Authority then had to move very rapidly to ensure the new terminal being ready for its first passenger in 1985 – an aim which despite some slippage will be fulfilled. They appointed Taylor Woodrow Construction as Managing Contractor in December 1979 to co-ordinate Construction.

Three preliminary comparative designs in structural steelwork, precast and in situ concrete were prepared for the basic framework of the building to establish the comparative costs and programme times for the different forms of construction. The result of these studies led to the choice of structural steelwork framing for the main building with floors constructed from composite profiled metal decking (Holorib} and in situ concrete. This form of construction was considered to be the most economical when both cost and time were taken together. Curtain wall cladding is used on the exterior of the building.

Effective structure

This choice of structure has proved particularly effective in terms of quickly providing virtually weathertight yet unobstructed areas.

The main building has a floor area of 97,000m2 and is framed with over 12,800 tonnes of structural steelwork, mostly of grade 50 to BS 4360.

The building framework is sub-divided into 12 zones each of which is braced to withstand wind-loading and other forces acting on it. At the junctions between these zones, at every 65 to 100 metres throughout the building, there are movement joints to accommodate thermal movements.

Floor slabs spanning 3.6m are carried by 10.8m long secondary beams spanning onto plate girders up to 18.0m long. Under the heavily loaded duty free shopping areas these girders weigh 8 tonnes and are designed for a loading of 20kN/m, elsewhere the floor loading is 5kN/m .

The slabs act compositely with profiled galvanised steel decking (Holorib) which also acts as the permanent form work to the slab. Special edge sections have been designed for this application. Services can closely follow slab construction as they are supported by hangers from the profiled steel decking.

The concrete roofs of the landside and airside departures concourses are supported on 2.6m deep welded tubular trusses up to 42m 1n length. Through these trusses, the air conditioning ductwork is routed with access to other services provided by walkways at bottom chord level. Over 18 kilometres of tube is used in their construction, of varying sizes up to a maximum of 273mm diameter x 25mm thick.

Whilst the structural steelwork for the terminal building is generally designed in accordance with British Standard 449, the elevated landside departures forecourt carries eight lanes of vehicular traffic and is designed for a modified class HA loading and to conform with British Standard 153.

Restricted depth available for deck construction resulted in heavy continuous welded plate girders rigid portal, with the largest span being 23.0m.

Secondary steelwork in this area was fabricated using heavy rolled. steel sections spanning 10.8m between the main plate girders with connections designed to provide continuity over lengths of 64.8m and 54.0m.

Fit of connections between columns and plate girders demanded trial assembly/erection in the Workshops to achieve the accuracy required. Main connections required the use of an average 120 high strength friction grip bolts per connection with bolts being torqued to a set sequence to ensure full fit-up of final connection with all bolts being effective.

In the Forecourt area a total of 60,000 high strength friction grip bolts were used, generally M30 and M36 diameter.

Under the departures forecourt where a mezzanine level is provided for office accommodation, the welded portal box columns incorporate specially designed shell brackets and rubber bearings to obviate vibration of the road above affecting the mezzanine level steelwork.

One hour fire protection is generally provided throughout the building, the structural steelwork being sprayed with ‘Pyrok’ protection after erection. after being initially blast cleaned and primed in the workshop during fabrication. Elsewhere exposed steelwork is cleaned and protected with paint and finished with a decorative topcoat.

Curtain wall cladding provides the outer shell for the building. This system is based on a repeating 1200mm module of glazing and composite aluminium panels providing the acoustic and thermal performance required. In addition a facing panel of deep drawn aluminium construction is projected in front of the composite panel to deflect the solar heat.

Sixteen gate lounge lobbies around the terminal are connected to the main building by single, double and three tier ramped link bridges which are generally of rolled steel angle lattice girder construction with flooring again comprising in situ concrete on Holorib metal decking. The bridges in some instances have welded box section column and tee head supports.

Fire protection

The gate lounge lobby and link bridge steelwork is generally fire protected by the use of a mineral fibre board with the Tee Post columns being protected by intumescent paint.

The APV building located behind the West Pier was not included in the original scheme and construction only started early 1984. The designers were faced with the difficulty of trying to accommodate an additional floor within the frame and still maintain the same overall height as the Main Building. To accommodate these objectives the structural zones were reduced to a minimum by using a through deck stud welding system to provide fully composite construction.

Derek Tordoff – BCSA