Projects and Features

Sustainability matters

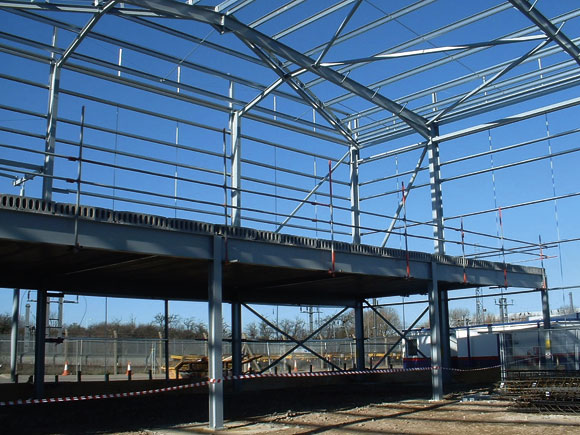

A new distribution warehouse near Heathrow Airport has fully demonstrated the sustainability of steel.

FACT FILE: ProLogis Park, Heathrow

Main client: ProLogis Developments

Architect: Michael Sparks Associates

Structural engineer: Terry Collier Associates

Main contractor: Norwest Holst Construction

Steelwork contractor: Barrett Steel Buildings

Steel tonnage: 230t

Sustainability is increasingly important in all aspects of construction, and using steel is seen as the most advantageous option because it is a recyclable material.

More often these days, gaining planning permission for a new development can actually hinge on the ability of the construction team to demonstrate a structure’s sustainable credentials.

Bearing in this mind, a new 55,000ft² warehouse was recently completed at ProLogis Park, Heathrow which boasts a structural steel frame which is 80% reusable when the building is de-commissioned.

Steelwork contractor Barrett Steel Buildings says it has followed a philosophy of the three R’s – reduce, recycle and reuse – for some time, and this helped it deliver the sustainable warehouse.

Tony Walker, Barrett’s Design Director says with these points in mind, the task was, with its client ProLogis, to design a building which could easily be disassembled and consequently maximise potential steel reuse, at no extra cost.

The building in question comprises 50,000 ft² of warehouse space, with a 5,000 ft² integrated office, as well as goods and entrance canopies. The structure has twin 23.6m spans, is 10m to underside of haunch, 99m long and includes predominantly 8m-wide bays.

All steel members were hard stamped with the section size and grade to allow identification when the building is deconstructed at the end off its useful life.

“At the design stage every member was value engineered to maximise potential reuse,” Mr Walker says. “In practice this means minimising welding and notching and maximising bolting, so that fittings can easily be removed,” he adds.

In total, Barrett says all the steelwork is ultimately reusable or recyclable, but for ease of operation 80% of the frame is easily reusable, and this breaks down to: 61% of the rafters being reusable; 79% of the portal columns; 95% of the floor beams; 87% of the valley columns; 83% of the gable posts; 95% of the bracings and 100% of the galvanised ground beams.

To endorse its sustainability credentials even further, Barretts has recently become one of the first companies to achieve accreditation to the BCSA Sustainability Charter and has achieved Gold Standard, which is the highest level.

Mr Walker says the majority of the steel erection was fairly straightforward except for the office block. “This two-storey structure is inside of the warehouse and features some tapered feature columns and also has a sunscreen mesh canopy which required some intricate connections for the supporting steelwork,” he adds.

Ken Hall, Senior Vice President, European Management Board for ProLogis Developments says sustainability doesn’t end at producing environmentally friendly buildings, it runs much deeper than that. “ProLogis encourages its suppliers to embrace the whole sustainability process,” he says.

“Sustainability matters to us, and having key suppliers such as Barretts to help us innovate is an important part of the process,” Mr Hall says.

“A sustainable business brings clear advantages both now and in the future of the business, the environment and for the wider community. Barrett is committed to leading the sustainability agenda in the steel construction sector,” sums up Barrett’s Managing Director Richard Barrett.