SSDA Awards

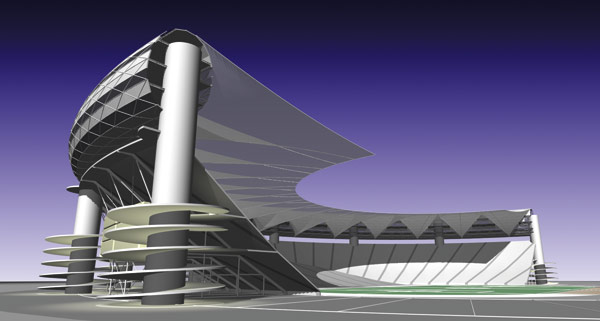

SSDA 2006 – Air Traffic Control Tower, Heathrow Airport

Steelwork was the material of choice for one of the tallest control towers ever built.

FACT FILE: Heathrow Control Tower

Architect: Richard Rogers Partnership

Structural Engineer: Arup

Steelwork Contractor: Watson Steel Structures

Construction Manager: Mace

Main Client: BAA

In the words of the judges, Heathrow’s new 87m high steel control tower is an iconic project, planned and executed in an exceptionally demanding environment.

The £50M air traffic control tower is now set to become one of west London’s most distinctive landmarks. It is said to feature the very latest in air traffic technology and offers controllers a 360-degree cone vision of the entire airport.

According to the National Air Traffic Service, Heathrow’s original control tower was in the wrong place and too small to meet the increased demands expected once Terminal 5 opens in 2008.

Taking the new terminal into consideration, a more centrally located tower was deemed necessary, one that could overlook the entire expanding airfield. So a position close to Terminal 3 was picked as the airport’s most geographically central position.

The logistical challenge facing the project team was primarily to design and construct the tower on an island site surrounded by live taxiways and aircraft stands in the centre of one of the world’s busiest airports.

The innovative solution they came up with was to pre-assemble as much of the tower away from the site as possible. This strategy allowed all the construction to take place at low level and the use of high crane jibs, which would have interfered with the airport’s radar, was minimised.

Tony Whitten, Contracts Director for Watson Steel Structures says the tower’s construction presented a whole range of unique challenges.

“Most of the work could only be carried out at night, when the airport wasn’t functioning. Logistically we had to assemble parts of the tower individually overnight, trucking in steel sections each time,” Mr Whitten explains.

The tower’s slender steel mast has a triangular cross section with a 4.8m diameter and this incorporates an internal and external lift, an escape staircase and service risers.

Richard Matthews of Arup and Engineering Leader for the project says during the planning stage a slender design was chosen to lessen the visual impact.

“A cable stayed structure lends itself to steel,” Mr Matthews says. “If we had used a traditional cantilever concrete tower the mast would have been well over twice the diameter of the cable stayed steel mast.”

The weight of the structure also played a critical role. To minimise any impact on the airport’s busy operation the tower’s cab was pre-fabricated on a remote site 1.4km away from the final location. The complete cab weighing approximately 860t, along with the necessary temporary works to maintain stability, was assembled and then moved into position during a night time closure of the runways.

The move took place on the night of 29 October 2004 and required three computer-controlled hydraulically powered flatbed units, each with 48 wheels. These carried the assembled cab a distance of 1,400m and the operation was completed in just two hours.

The next day the assembly was lowered and connected to the first mast section which had already been positioned and which was supported upon a series of jacks forming an hydraulic pin for use during the mast erection.

The jacking operation was one of the most complex ever carried out in the UK. A set of three strand jacks on 20m high temporary towers were used to lift the cab structure into the air while a section of mast was installed below. The jacks were reset and the operation repeated five times until the cab was at its final height.

During the lifting process three temporary guy cables were required to stabilise the top of the tower. These were eventually replaced by six permanent 150mm diameter cables and finally the entire 1,150t structure was made secure by tightening the holding bolts to a pre-determined tension to obviate any fatigue loading on the bolts.