Projects and Features

From niche profiling to specialist fabricator

Jamestown delivers components for infrastructure projects

During the last 20 years Jamestown has developed into one of the UK and Ireland’s leading steel specialists.

Since its beginnings more than 20 years ago, Jamestown has developed from a niche profiling company to an independent specialist fabricator. Having successfully weathered several economic cycles, Jamestown is now one of a select number of independent specialists offering design, fabrication and fully-automated welding of plain and cellular plate girders. In addition, Jamestown delivers the manufacture of heavy components across many sectors including highways, rail, construction, marine, port and crane, and machine building.

“Collaboration, partnership and supply chain integration are fundamental to Jamestown’s mission statement,” says Jamestown Director Fiacre Creegan. “We hold our customers’ requirements in very high regard and work closely with them to understand their needs and translate them into the finished product.”

Jamestown joined BCSA several years ago, and committed in 2016 to becoming a Headline Sponsor of Steel for Life, demonstrating a keen interest in the promotion and development of the steel industry generally. “The sector operates in a very dynamic way with standards, quality levels and accreditations being critical to progress and success,” says Mr Creggan. Jamestown recognised this early on and were early adopters of CE marking, achieving Execution Class 4, NHSS 20, and BS EN 3834 compliance. “This, combined with our strong approach to customer and client liaison, has helped Jamestown achieve a high level of involvement in both the Irish and UK markets,” he adds.

Investment and Growth

Investment in people and processes, as well as consistent research and development, have been hallmarks of Jamestown’s success over the past 10 years.

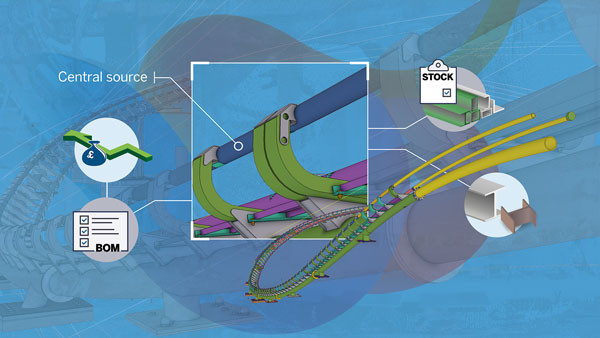

Investment has included installing the latest automated welding technology on all three of their automated plate girder lines, which demonstrates a clear commitment to growing the business. This, combined with a move in late 2015 to a large scale 200,000 sq feet production facility with 24, 15 and 20t overhead cranes on a 17 acre site, allows Jamestown to offer a wide-ranging service. “We can now trial erect or trial assemble bridge structures of up to 200t and 150m in length in our new facility” says Mr Creegan.

“It has been our specialist knowledge in welding, welding processes, weld testing and weld design that has helped us to get where we are today,” says Niall Fortune, Jamestown’s Responsible Welding Coordinator and Beam Production Manager. “We can now produce beams on single or double-shift across one, two or three machines. This gives clients the absolute confidence that Jamestown can comfortably meet the most demanding of project programmes, and can manufacture a quality assured product every time.”

The company supplied the roof beams for Leicester Tigers’ new stand

A new facility allows the company to trial assemble large structures

Sectors

Jamestown has succeeded in growing into many sectors including rail where it has produced individual components up to 100 tonnes in finished single pieces. “The Foxhall Lane Bridge was a particularly interesting project”, said Mr Fortune. “It involved 40m-long, 2m-deep Western Region-type trapezoidal box girders made from weathering steel. Traditionally these box girders had to be painted internally, which is a high risk procedure. Weathering steel was chosen to eliminate this risk by not requiring anyone to enter the box. The aesthetics of the bridge was maintained by painting the external areas offsite.”

With critical elements such as cambers, bearing positions and cross beams with faying surfaces, a full trial erection ensured all elements fitted together before going to site.

In more ‘typical’ steel construction projects, Jamestown has supplied plate girders to projects like Farringdon Station, the Olympic Stadium, Reading Station redevelopment, Blackburn Bus Station, and St James’ Square just to name a few. Mr Fortune says: “With our plate girders there is almost infinite flexibility in design which can help reduce costs and have a broader offering in cell positions and beam depths.”

In the port and crane sector, Jamestown applies its high-end welding skills to the manufacture of lightweight crane legs and tapered box girders. “These items demand very specialist knowledge and experience, and are complex due to light gauge plate being used,” says Aidan Clear, Jamestown’s Production Manager. Correct fit-up is essential on these large items with such tight tolerances so a full trial fit is completed and checked with laser trackers.

Highways is a relatively new sector for Jamestown, having just completed under subcontract a significant bridge scheme involving three separate bridges on the A30 in Cornwall. Our client was delighted,” says Richard Wigglesworth, Jamestown’s Project Manager, “with bridge lifts fitting perfectly onto bearings and each lift being completed ahead of schedule.”

The Future

Jamestown’s commitment towards development and growth within the steel sector is clear. “There is plenty of room for those who offer a quality product, and have the resources and capability to go beyond the industry norm,” says Mr Creggan. “We feel that although the market is mature, there is still a level of acceptance of existing practices which needs to be challenged.

“Clients can benefit from being given more options than they have perhaps been offered to date. We see that with a broadening of knowledge of design and manufacturing processes, clients can come to understand the options available to them.”

Jamestown’s move into the area of beam design has been coupled with a greater level of value engineering with client and contractor engineers and managers. ‘This has been very successful so far and the benefits of this collaboration have been shown in terms of cost savings across projects in recent years.,” says Mr Creggan. “This was evident in the steelwork for the new stand at Leicester Tigers where specific plate thicknesses and lengths were rolled to reduce the overall weight and eliminate waste.”

Mr Creegan concludes: “We will continue to grow our presence in the UK market and look forward to growth across all the sectors in which we operate. No doubt there will be challenges, but with the mix of people and the experience within our organisation, Jamestown looks optimistically to the years ahead.”

Jamestown Cladding & Profiling Ltd is a headline sponsor of Steel for Life.