Projects and Features

Design and manufacturing with computer software

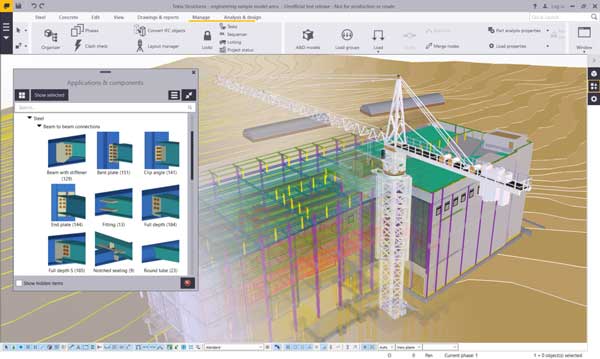

The transition from 2D to 3D models has improved design team communication and workflow

In this article NSC examines how computer software supports the full steelwork design and manufacturing process, the benefits it delivers to the steel construction sector and how it might evolve in the future.

The steel construction sector has been utilising 3D design software for over 25 years and is well versed in the benefits and efficiencies it provides to manufacturing and construction programmes. Today computer software is integral to the design, fabrication, erection and everyday operational processes at most steelwork contractors’ facilities.

Software is seamlessly interwoven into each stage of the steel fabrication process supporting activities such as knowledge and bid management, project planning, frame analysis, connection design, 3D modelling, BIM co-ordination and the fabrication process itself.

At the earliest stage, modelling and estimating software plays an essential role in the bidding process for the steelwork contractor, and its use is increasing. This software provides the ability to create a model of the steel frame so steelwork contractors can visually present the content of their bid alongside the associated costs, provide insight into the sequence of construction works and identify solutions to reduce health and safety risks.

The practiced use of 3D modelling software allows steelwork contractors to create a virtual prototype of the steel frame, and is one of the most important pieces of software a steelwork contractor uses today. Data from the model can then feed into many business processes. Importantly, data from other parties can be imported into the modelling software and the steel model can be exported in Industry Foundation Classes (.IFC) format for use by others. It’s this function which plays an important role in the adoption of BIM.

During the design phase, the structural steel will be modelled to facilitate fabrication. Materials Resource Planning (MRP) software then processes the bill of materials data from the model which is used for procurement of materials, manages data to drive automated cutting and fabrication machinery, plans logistics, as well as piece weights for crane planning. MRP software can also be used to monitor progress of fabrication by capturing data about each part as it passes through the different fabrication processes.

Moving beyond desk-based software and from 3D to mixed reality

Already data is being transferred from the model to site and back again. Advances in software interoperability means that specific data from a design model can be imported directly to the surveying equipment used on site. The process can also be carried out in reverse, enabling data captured on site to be imported back into the construction model for compliance and comparison purposes.

Actual progress of the works can also be captured and reported back using an increasing number of mobile devices and Apps available for use on-site.

Over the last few years the transition from 2D documents to 3D models was a natural evolution, which improved team communication and coordination. However, further technological advancements will drive the adoption and advancement of mixed reality and holographic technology, which will bring 3D models out of the screen and provide users with the ability to engage and interact with design data more intuitively.

By being able to view holograms of 3D structural frames in the real world, engineers will be able to visualise a variety of constructions on site to see what they will look like, and confirm if they can physically be created.

For steelwork contractors, while viewing the 3D holographic image they will be able to isolate connections and extract them from the model to see if they are correct and if they can be fabricated in the workshop.

This device and technology will not only work on a building site or in cities, but in workshops, where steelwork contractors could wear the headset to see if there are any missing components, such as bolts, or anomalies within the structure, and physically use the hologram as a guide to creating the steel components.

The technology could also be used to perform a ‘construction rehearsal’ where the steelwork contractor and site staff virtually walk through the construction sequence and connection processes. This would ensure the steelwork contractor’s detailing aligns with the erection team’s preferred method of assembly, before manufacturing instructions are sent through to production.

Sponsors

Sponsors

Computer Software

Silver: Trimble Solutions (UK) Ltd

Thanks to Trimble Solutions (UK) Ltd for contributing to this article