News

Aluminum foundry relies on steel

An important foundry that will produce components for the UK’s car manufacturing industry is being erected by Caunton Engineering.

An important foundry that will produce components for the UK’s car manufacturing industry is being erected by Caunton Engineering.

The aluminum casting facility in Telford is being built by McLaren Construction for global giant Magna International. Once complete, the foundry will supply products to Jaguar Land Rover.

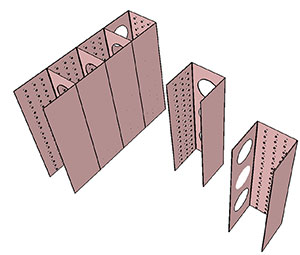

The building is a twin-span portal frame with lean-to sides, measuring 204m by 84m. The overall plan area of the building including an attached shipping area is 20,900m² and this will require over 1,300t of structural steelwork.

The steelwork is being designed by Caunton’s own technical team and they said that, due to the fatigue actions induced by large gantry cranes, elements of the steel structure had to be specified as Execution Class 3 (EXC3) for CE Marking purposes.

This places more stringent requirements on the fabrication and welding processes.

Once production begins in 2018, the facility will use Magna’s innovative high-pressure vacuum die-casting process to produce a number of advanced lightweight aluminum castings, which are a key building block in the next generation of all-aluminum and multi-material vehicle architectures.

By using these types of castings, Magna says it helps carmakers deliver maximum strength and stiffness with minimum weight, that ultimately achieves better fuel economy, safety and handling.